Water Saving | Case Studies

CORR™ system | Japan

To introduce a case of water savings in the electronics industry.

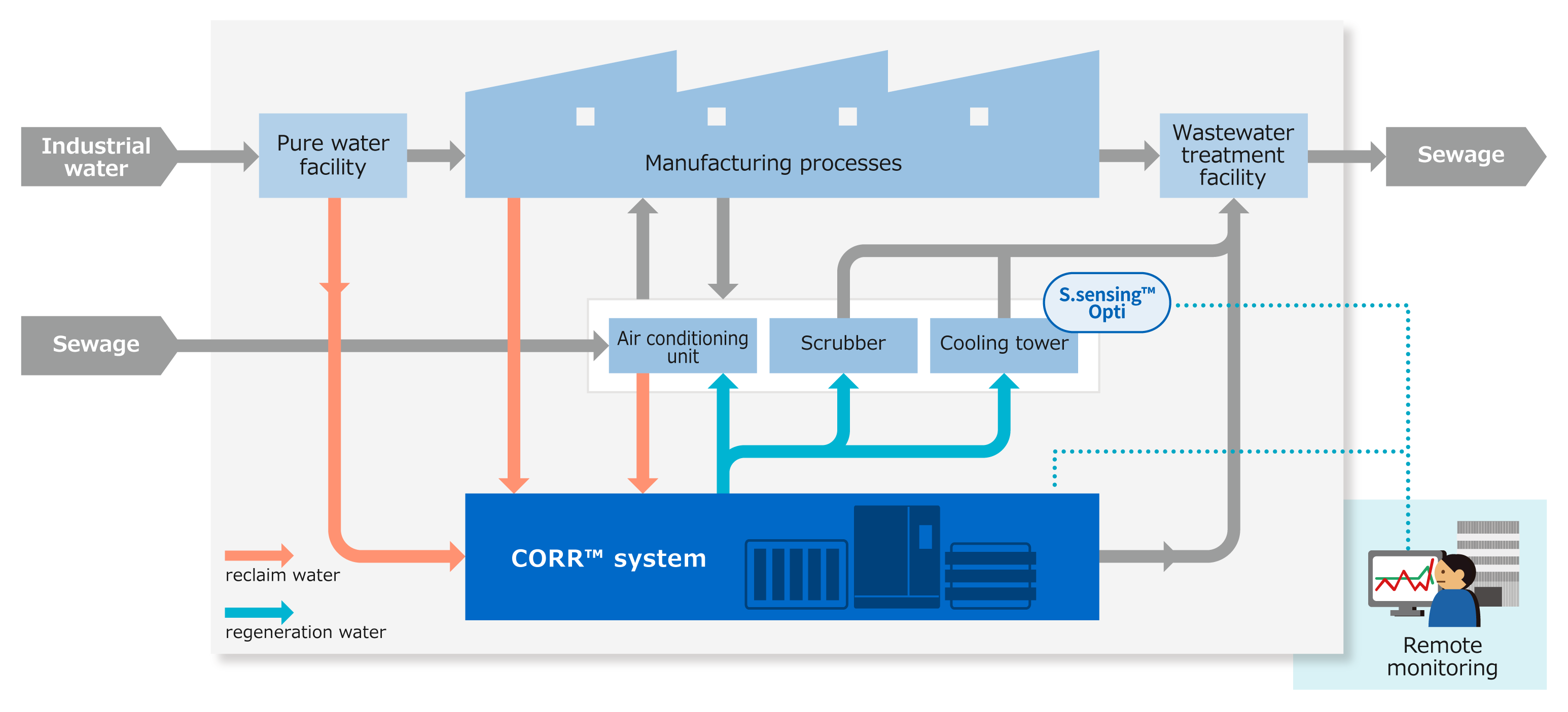

Reduction of tap water usage by reclaimed water supply services using the CORR™ system

Semiconductor manufacturing uses large amounts of ultrapure water in processes such as cleaning and also uses a lot of water to cool manufacturing equipment; therefore reducing water usage is a significant challenge for the customer. The Kurita Group proposed reclaimed water supply services to reclaim and reuse wastewater generated in semiconductor manufacturing processes, thereby contributing to reducing the amount of tap water the customer uses.

Workload and total cost to operate and maintain wastewater reclamation system

wastewater from factories is usually purified by Wastewater Treatment Systems to a level that does not impact the surrounding Environment, and then Release into sewers and rivers. If this wastewater could be reused as "recycled water," it would be possible to significantly reduce the amount of Tap water used. However, because factory wastewater places a high burden on water quality and the range of fluctuation in water quality is large, the number of units that make up the Wastewater reclamation system and the number of chemicals used increase, and customers considering introducing such equipment face the challenge of reducing the effort required for operational management to ensure stable operation, as well as reducing initial and running costs.

Reclaimed water supply services, including all works of system installation and operation management by Kurita

Wastewater from factories is usually purified by wastewater treatment systems to a certain quality level that does not affect the surrounding environment before being released into sewerage and rivers. If this wastewater can be reused as "recycled water" it is possible to reduce tap water usage significantly. However, factory wastewater carries a high burden and a large fluctuation in water quality. Therefore, because the wastewater reclamation system consists of many parts and uses many kinds of chemicals, reducing workload for stable system operation and maintenance, as well as initial and running costs, became an issue for customers considering installing the system.