GHG Emissions Reduction | Case Studies

Heat pump | Japan

To introduce a case of GHG emissions reduction in the electronics industry.

Using heat pumps to reduce GHG emissions according to reduced steam for pure water heating

The customer, which manufactures power semiconductors, had been proceeding with various initiatives to achieve its environmental targets, such as energy savings and reduced GHG emissions, and reducing plant-wide steam usage was one of its problems. The Kurita Group contributed to achieving the customer’s targets by collecting and reusing the exhaust heat in the factory using heat pumps in the pure water production process.

Using large volume of steam in the pure water production process

In the pure water production process, particularly in RO membrane system, the raw water must be supplied at a certain temperature, so a large volume of steam is used to heat it. Therefore, reducing the amount of steam used in pure water production helps to reduce energy use and GHG emissions.

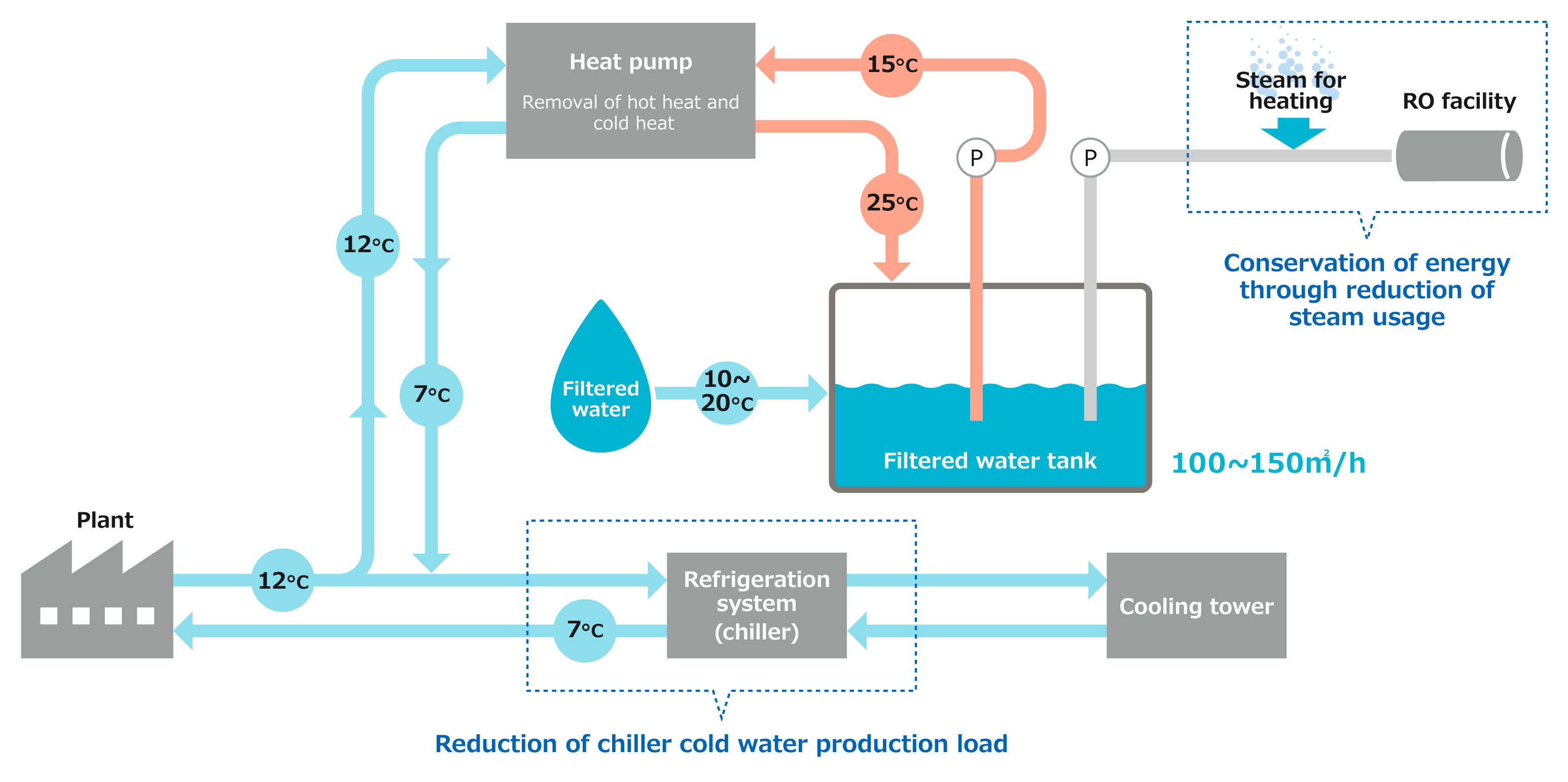

Applying heat pumps to use the exhaust heat of the refrigeration equipment or in the pure water production process

To solve this problem, the Kurita Group proposed recovering the waste heat from the return water of the heat pump and using it to heat the Raw water for producing Pure water . This reduced the amount of steam used in producing Pure water by approximately 60%, and also reduced the load on the chillers by using the return water after heat recovery again as Cooling water for the cooling tower . The reduction in steam usage and the load on the chillers made it possible to reduce GHG emissions for the entire factory by approximately 600 tons per year.