Recycling and Reducing Resource Input| Case Studies

S.sensing™ CS | Japan

To introduce the case reducing resource inputs in the electronics industry.

Reduction of chemical-derived sludge in wastewater treatment through S.sensing™ CS

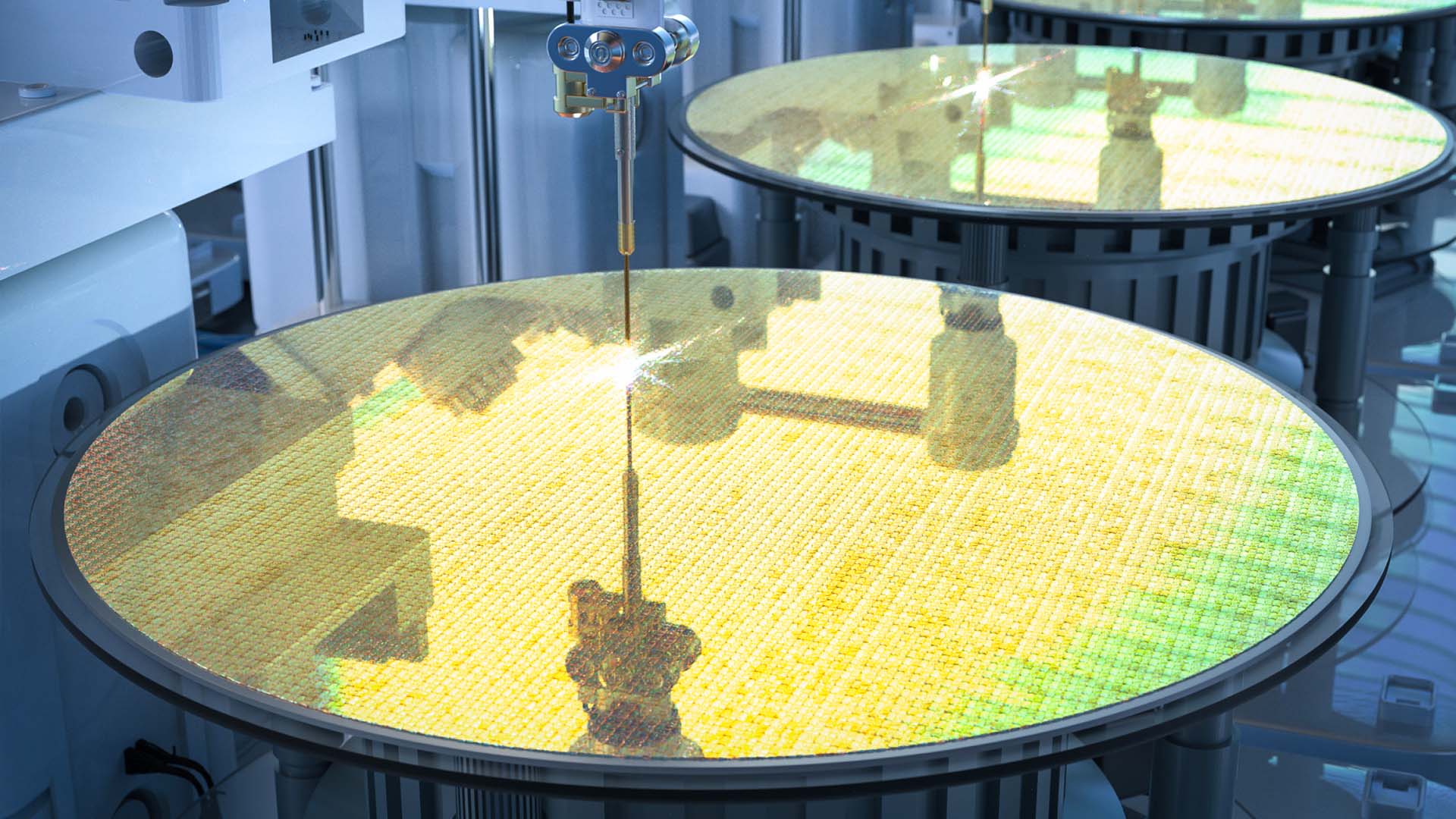

In the semiconductor manufacturing process, large quantities of fluorine-based cleaning chemicals are used in the etching and cleaning processes, and the waste liquid from this manufacturing process is disposed of as industrial waste (sludge) following coagulation and sedimentation treatment. The Kurita Group proposed and provided a solution to optimize the amount of chemicals injected by S.sensing CS, its automated chemical injection management system, for the customer's wastewater treatment system, contributing to reducing the amount of chemical-derived sludge (amount of resource inputs) generated.

Increase in chemical-derived sludge generation, sludge disposal costs and chemical costs

The wastewater treatment process first injects chemicals, such as inorganic coagulants and polymer flocculants, into the wastewater in a coagulation tank to turn the suspended matter into large flocsmass blocks (flocs). After that, these flocs are allowed to precipitate in a sedimentation tank, removed as sludge, dehydrated, and disposed of as industrial waste. The fluoride concentration in wastewater from the semiconductor manufacturing process fluctuates significantly, increasing and decreasing according to the amount of fluorine-based detergent used due to changing the operating status of production lines. Therefore, to carry out stable wastewater treatment, inorganic coagulants must be injected in alignment with the maximum concentration of fluorine. However, if the fluorine concentration is low, excessive injection occurs, and the amount of chemical-derived sludge generated increases, leading to higher costs of sludge disposal and chemicals.

Achieving both stable quality of treated water and reducing sludge generation by S.sensing™ CS

The Kurita Group proposed S.sensing CS to the customer to optimize the amount of chemical dosing utilizing sensing technology. A coagulation sensor installed in the coagulant tank continuously measures turbidity between flocs and fluorine concentration and feedbacks the results to S.sensing CS in real time to optimize inorganic coagulant dosing. As a result, the amount of inorganic coagulant used and amount of chemical-derived sludge generated was reduced by around 50%, helping to reduce resource inputs.