Recycling and Reducing Resource Input| Case Studies

OSCAR™ | Europe

We will introduce examples of resource recycling and resource input reduction in the petroleum industry.

Using the off-site membrane cleaning and regeneration service “OSCAR™” to recycle NF membrane wastes

The key component of a seawater treatment plant is an NF membrane treatment equipment to remove the ions as the cause of scale formation. Due to membranes being clogged with use, they are cleaned or replaced at certain intervals. It is difficult to get fresh water for membrane cleaning on sea platforms and to secure somewhere to release the wastewater containing cleaning chemicals, and then discarding used membranes and replacing them with new membranes is usual. Therefore, reducing costs with membrane replacement and waste volume from used membranes was a significant problem for the customer.

NF membrane replacement costs

The key to seawater treatment plants is the NF membrane treatment device, which removes ions of substances that cause scales . As the membrane becomes clogged with use, it must be cleaned or replaced at regular intervals. On platforms installed at sea, it is difficult to obtain fresh water for membrane cleaning or to secure a Release destination for cleaning wastewater containing cleaning agents, so it is common to discard used membranes and replace them with new ones. For this reason, reducing the costs associated with membrane replacement and reducing the amount of waste from used membranes were major issues for our customers.

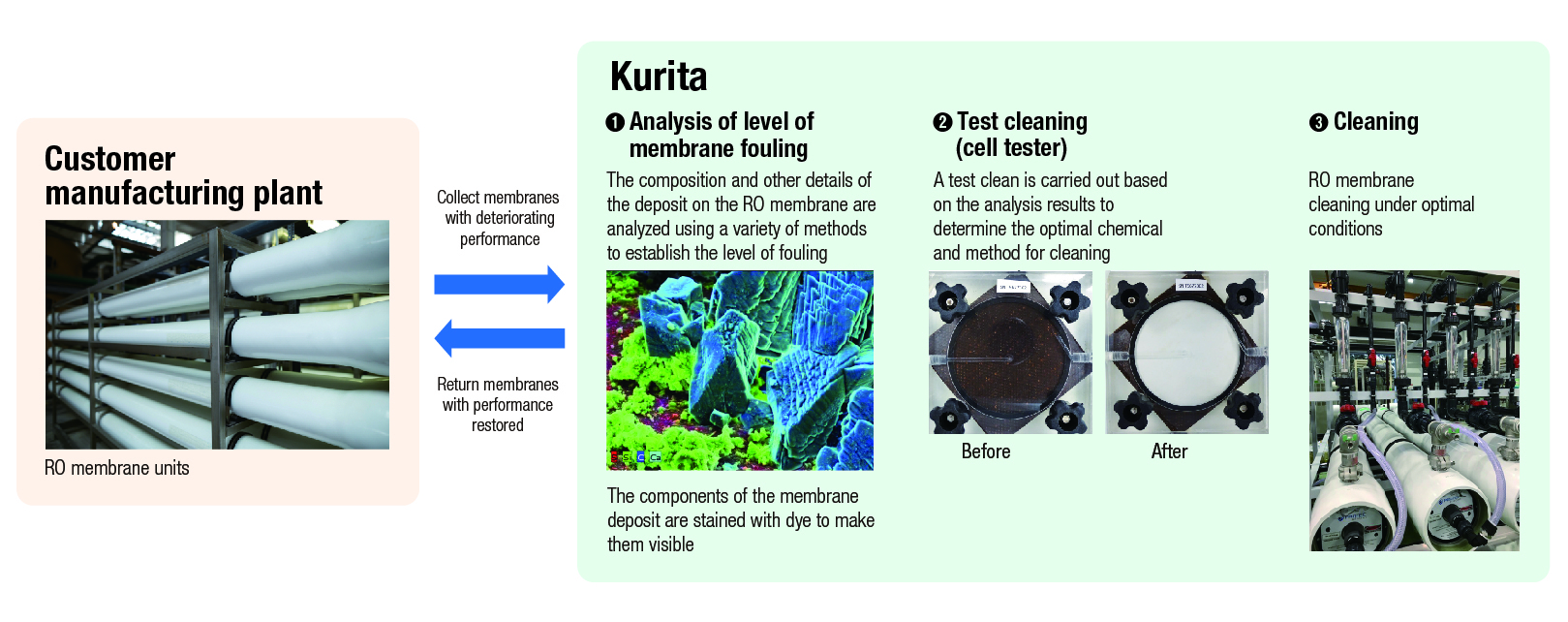

Applying the “OSCAR” service, the offsite membranes cleaning

The Kurita Group proposed the offsite cleaning and restoration of the NF membranes by “OSCAR(offsite cleaning and restoration)” service. This service cleans used membranes by the cleaning equipment in the Group’s factories, specifically designed to keep optimal flow rate, water temperature, and cleaning pressure, using various detergents, with the confirmation of its performance recovery by the performance test before cleaning and after that. Even membranes that are discarded because they are not restored by conventional treatment can recover their performance near the new level. In this case, the OSCAR service has cleaned over 200 membranes and succeeded in restoring more than 90% of them. This case reduced membrane replacement costs compared with changing new membranes and contributed to recycling NF membrane waste into resources.