Water Treatment Chemicals| Services

Maximizing the function of water with the power of chemistry

Applying water treatment chemicals to customer plants and equipment helps improve productivity and stable operation.

About water treatment chemicals

Water treatment chemicals are applied to make water quality suitable for equipment. By utilizing the technologies and knowledge cultivated since its foundation, the Kurita Group provides the most suitable water treatment chemicals for each customer's equipment and usage, such as boilers and cooling systems for factories, air conditioning systems for office buildings, manufacturing and production processes in various industries, and wastewater treatment systems in factories.

Boiler water treatment chemicals

Water treatment chemicals are applied to boilers that generate steam, using heat and power sources for facilities in factories and other locations. These chemicals contribute mainly to the stable operation of boilers and energy savings by preventing corrosion and scale-related deficiencies in boiler water systems.

Improve and maintain heat transfer coefficient by dispersing and removing scale on boilers

Challenges

Scaled boilers inhibit heat exchange and cause various problems, so boiler water treatment chemicals are indispensable to prevent scale for maintaining the heat transfer coefficient and durability of equipment. However, conventional boiler water treatment chemicals that disperse scale components can cause scale exceeding the chemical’s processing capacity, requiring separate treatment with scale-removal chemicals.

Solutions

Boiler water treatment chemicals, which contain DReeM Polymer™ to disperse and remove scale, have the distinct feature of being able to prevent and remove scale quickly and effectively. These chemicals can constantly clean boiler heat transfer surfaces, maintaining high efficiency and contributing to their stable operations. These features enable energy-saving operations and reduce GHG emissions by reducing energy consumption. Furthermore, reusing drainage water as boiler water and operating boilers in high concentrations contribute to water savings by reducing the amount of blowdown.

Water savings

Energy savings

GHG emissions reduction

Stable operation quality

Cooling water treatment chemicals

Cooling water treatment chemicals are applied to water circulating in refrigera tion system heat exchangers and cooling towers, which are indispensable for cooling processes in factories and air conditioning in office buildings. These chemicals prevent the three biggest problems affecting cooling water systems: corrosion, scale, and slime. This allows for the system to remain stable and save in both water and energy.

Prevent problems in cooling water systems by suppressing the growth of Legionella bacteria, achieving stable operation of equipment and energy saving, and reducing the risk of infectious disease outbreaks

Challenges

Problems in cooling water systems cause issues like shutting down cooling processes and air conditioning equipment, shortening equipment life, and energy loss. In addition, Legionella bacteria may grow in circulating water in cooling water systems. When circulating water containing grown bacteria scatters from the cooling tower as aerosol, there is a risk that people may catch Legionnaires' Disease, with high fever, headaches, breathing difficulty, and pneumonia. Therefore, it is required to prevent problems and suppress the growth of Legionella bacteria in cooling water systems.

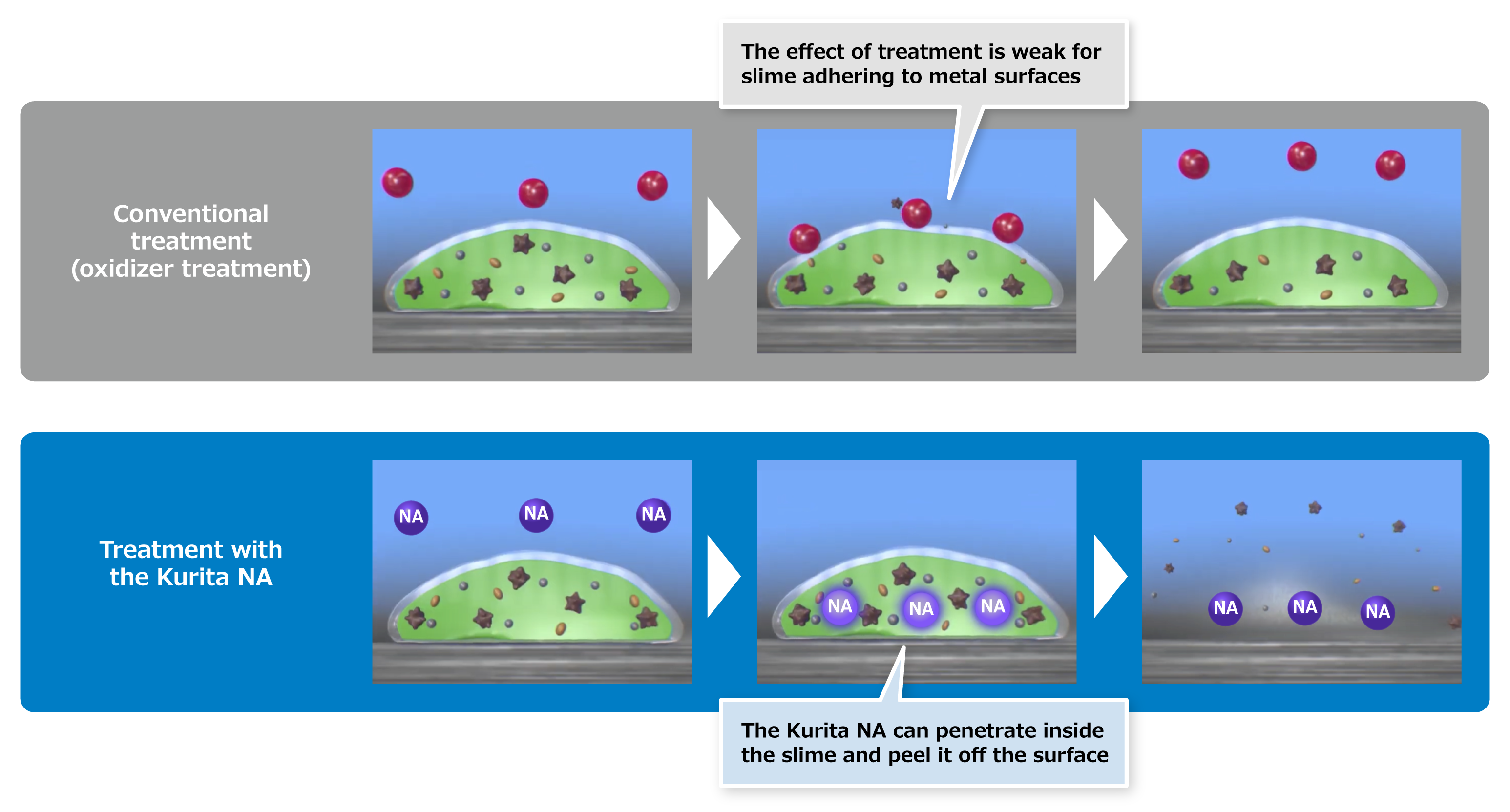

Solutions

In addition to preventing operational challenges, the Kurita NA™ series, which suppresses the growth of Legionella bacteria, prevents a decrease in heat transfer coefficient by the adhesion of slime to heat exchangers in refrigeration systems. This contributes to reduced electricity consumption and GHG emissions. Furthermore, Kurita NA™ series suppresses the generation of scale by the concentration of hardness components, such as calcium carbonate, and increases the concentration factor of cooling water, contributing to water savings. Moreover, it has a strong effect to reduce the viability rate of Legionella bacteria to 1/10th , maintaining a hygienic facility environment.

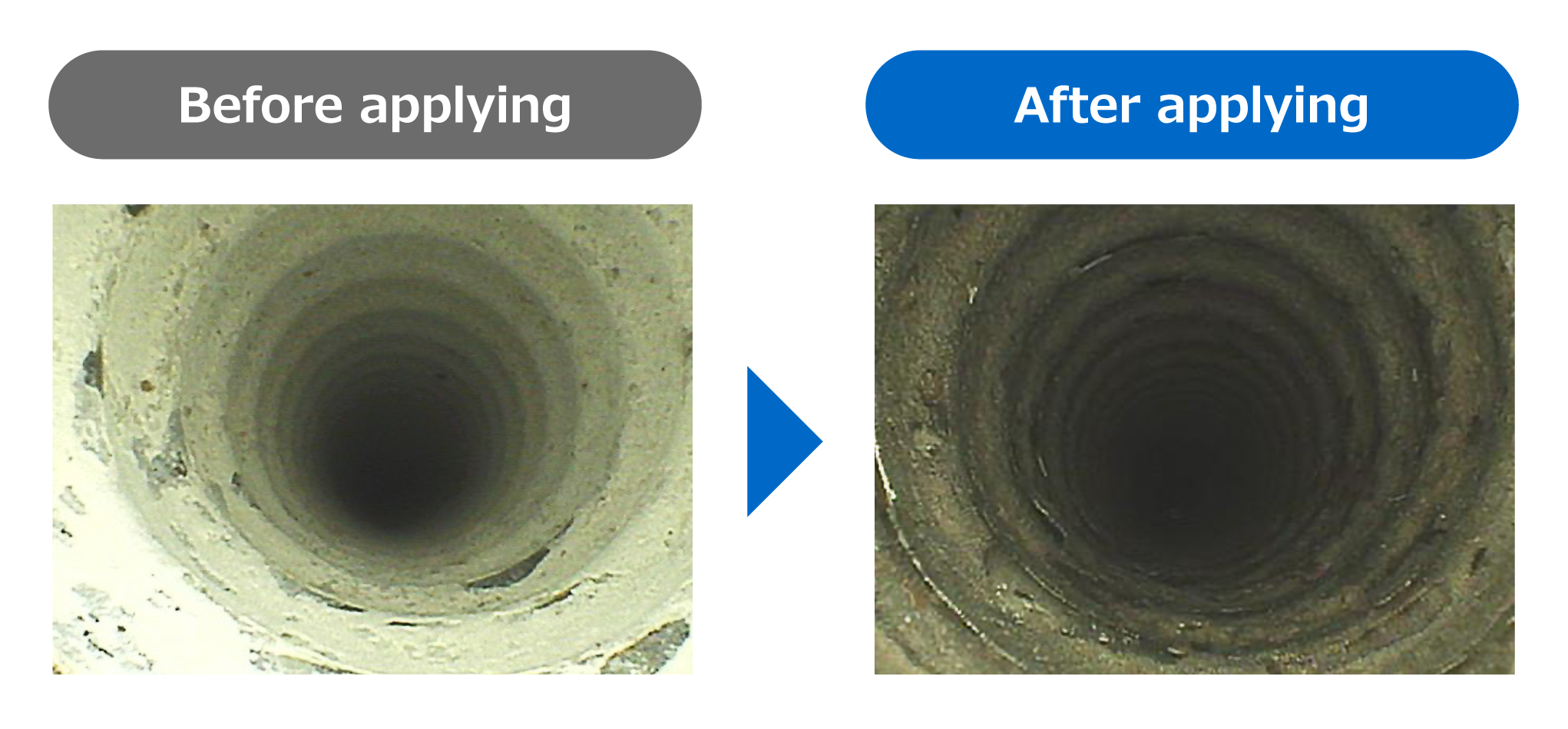

Slime adhesion to cooling tower distribution board

Water savings

Energy savings

GHG emissions reduction

Keeping cleanliness condition

Wastewater treatment chemicals

In the treatment of wastewater, processes are needed to remove suspended solids and harmful substances to achieve suitable water quality, dehydrate sludge, and neutralize odors. By providing a wide range of chemicals to these wastewater treatments, Kurita Group contributes to reducing environmental impact and waste output due to wastewater.

Reduce chemical costs and the amount of chemical-derived sludge generation (resources input) by optimizing the amount of wastewater treatment chemicals input and stabilizing wastewater treatment

Challenges

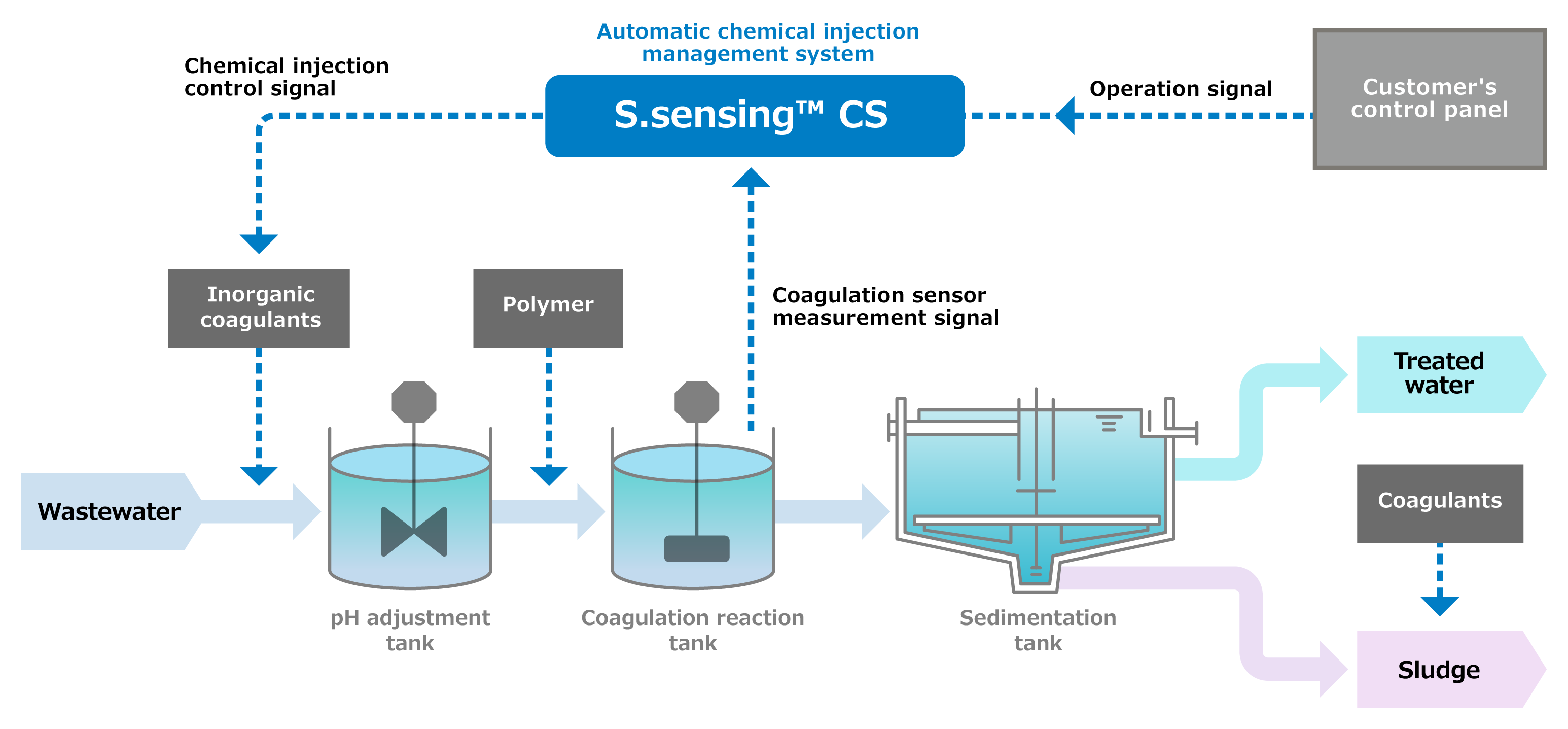

The concentration of substances in wastewater changes according to various conditions, such as production items and volumes. To stabilize wastewater treatment operations, it is popular to set the injection amount of wastewater treatment chemicals based on the assumption of a constantly high concentration of the substance to be treated. However, this can increase chemical costs due to over-injection, the amount of sludge generated from chemicals, and sludge disposal costs.

Solutions

The S.sensing™ CS, which optimizes the injection amount of wastewater treatment chemicals automatically using a unique sensor, can control the injection amount of chemicals according to the changes in the wastewater quality in real-time, reducing of chemical costs and the amount of chemical-derived sludge generated. In addition, the remote online monitoring of operational status contributes to labor-saving in operational management processes.

Reduction of Resource Input

Labor resource saving

Cost reduction

Stable operation quality

Chemicals for production processes

Kurita offers a wide range of chemicals for unique manufacturing and production processes in various industries, improving productivity and saving energy.