Operation and Maintenance| Services

Support customers by providing assurance and safety

On behalf of the customers, the Kurita Group manages operations and maintenance for various water treatment systems, ensuring the effective and stable operation of their facilities.

About operation and maintenance

The Kurita Group's highly experienced engineers conduct a range of management works on behalf of customers, such as operational management, utility management, and equipment repair at water supply and wastewater treatment plants, sewage treatment plants, ultrapure water supply systems, and wastewater treatment systems.

Operation and maintenance of water treatment facilities

The Kurita Group conducts optimum operational management at facilities. By conducting on-site surveillance and remote monitoring, we manage facilities through routine visits, to track the operational status of equipment and water quality, and prevent problems from developing. We also craft and implement medium- and long-term maintenance plans based on operational data obtained from facilities to help extend the service life of equipment.

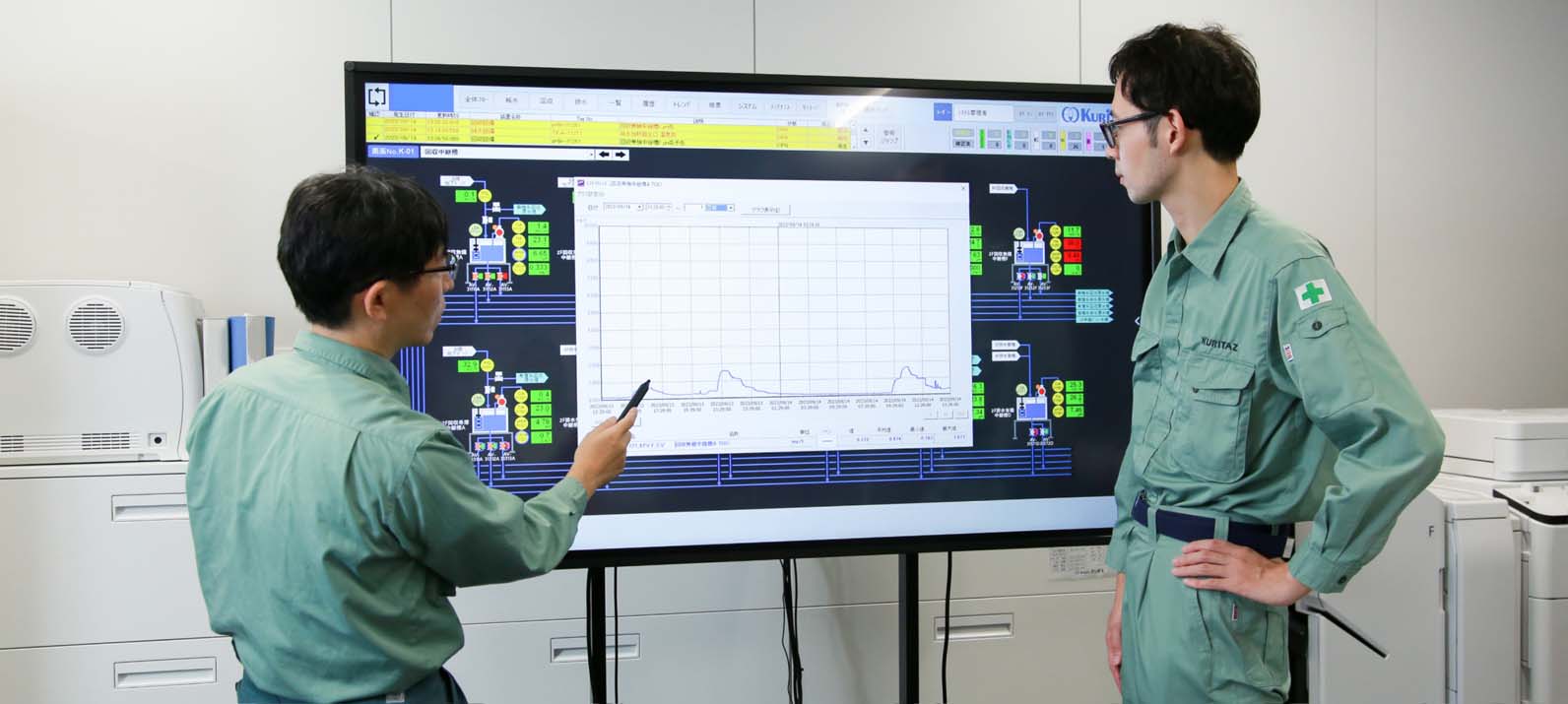

Remote monitoring system to improve work efficiency and achieve stable facilities operation

Challenges

While central monitoring systems such as those at human waste treatment plants already respond to remote and real-time display of the operational status and automatic alarm in the event of an abnormality, the facility operation needs to be done by the administrator in the central monitoring room. In addition, since acquiring main data, such as water volume, by systems remains part of them, simple analyses and inspections are frequently needed. Moreover, supplementing their results with paper-based records makes operational work more complicated.

Solutions

The Third-S™ is a monitoring system that ensures safe, secure, and stability of facility operation. It enables operators to check the facility’s operating status anytime and anywhere from a computer or smartphone device, as well as from a central monitoring room. In addition, it can create a database by accumulating data, which would be utilized for troubleshooting and predictive management. This system can save workloads in operation and maintenance by improving facility inspection efficiency. Moreover, it helps the operator promptly recognize trends and abnormal values in data, enabling stable operation to continue through early preventive maintenance.