Precision Tool Cleaning | Services

Remove nano-level contaminations invisible to the naked eye

The Kurita Group analyzes the particles on the semiconductor manufacturing equipment and performs a thorough clean and surface treatment, improving productivity.

About precision tool cleaning

In semiconductor manufacturing, the equipment will gradually adhere and accumulate “dirt” as part of the production process. Then the particles can collect onto the product, leading to a decline in product yield. The Kurita Group offers precision tool cleaning services that clean a variety of parts of semiconductor manufacturing equipment at our facilities to remove microparticles and ionic substances.

Apply optimal cleaning methods to improve production yield and enable reuse of parts and tools

Challenges

There are various kinds of materials and parts used in semiconductor manufacturing equipment, and there are many types of particles that adhere to them. In the cleaning process, particles must be removed reliably without damaging the base material or equipment parts.

Solutions

The Kurita Group proposes optimum cleaning methods according to the materials and parts. Chemical cleaning is a method of soaking dirty parts in a chemical solution and removing the dirt , enabling them to clean objects with complex shapes and structures uniformly in every corner. This cleaning method uses an unique combination of specialized chemicals, such as acids, alkalis, and organic solvents. Physical cleaning methods are applied to specific materials corroded by chemical cleaning and dirt that cannot be removed completely, using high-pressure water, blasting, ultrasonic cleaning, and polishing. The Kurita Group has dedicated equipment for physical cleaning of large parts. Reliable cleaning by different methods improves production yields in semiconductor manufacturing and the recycling by reuse of parts.

Recycling

Productivity improvement

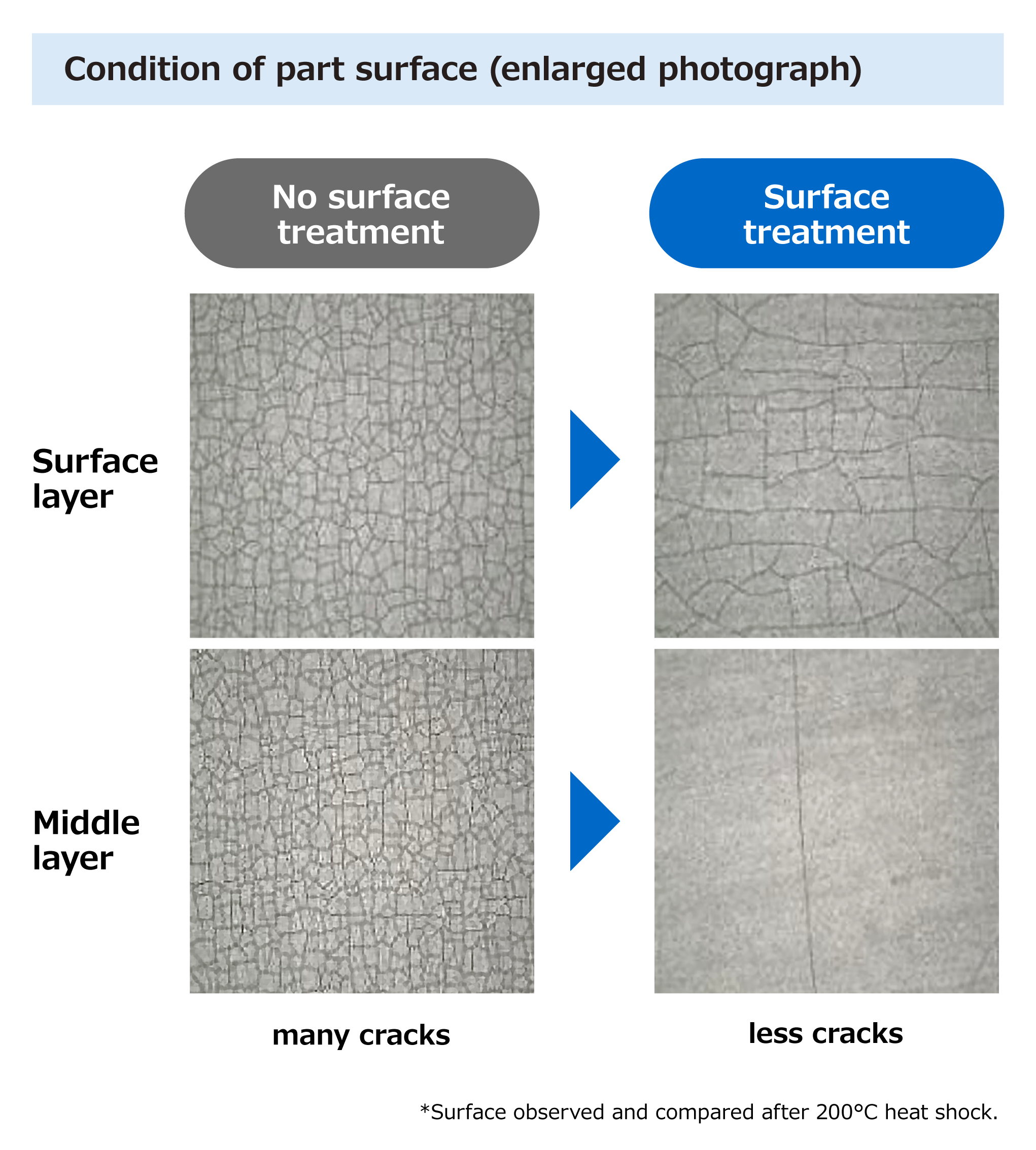

Recycle parts that are prone to cracks through surface treatment and cleaning

Challenges

Materials used in semiconductor manufacturing equipment are prone to cracks due to corrosion and thermal stress. For their repeat use, it is necessary to improve corrosion resistance and material durability.

Solutions

To increase corrosion resistance and durability, parts and materials used in need to be treated on their surface with thermal spraying, gold-plating, or coatings. The gold-plating and coatings can also be removed in the cleaning process and their surfaces treated again. These surface treatments and cleaning extend the service life of parts and the recycling of resources through reuse.