Automotive | Industries

Preparing the painting base with water

Introducing the solutions for the automotive industry.

Kurita Group solutions for the automotive industry

The automobile painting process is divided into the surface treatment, electrodeposition process, and the painting process (painting booth). In the surface treatment and electrodeposition processes, water rinsing is performed to remove foreign substances adhering to the body. If the water quality used for rinsing deteriorates, paint defects can occur, requiring correction and repainting. Next, middle and topcoat paint are sprayed onto the body in the paint booth. In a wet paint booth, water is used to collect excess paint that has not adhered to the body, and this water is reused as circulating water after being separated from the paint. However, if paint remains in the circulating water, it can generate unpleasant odors or cause the painting process to be suspended due to a blocked pipes. The Kurita Group provides solutions to solve problems that arise in the surface treatment, electrodeposition process, and painting processes, contributing the removal of foreign matter, the separation of paint and water, and the prevention of unpleasant odors in circulating water.

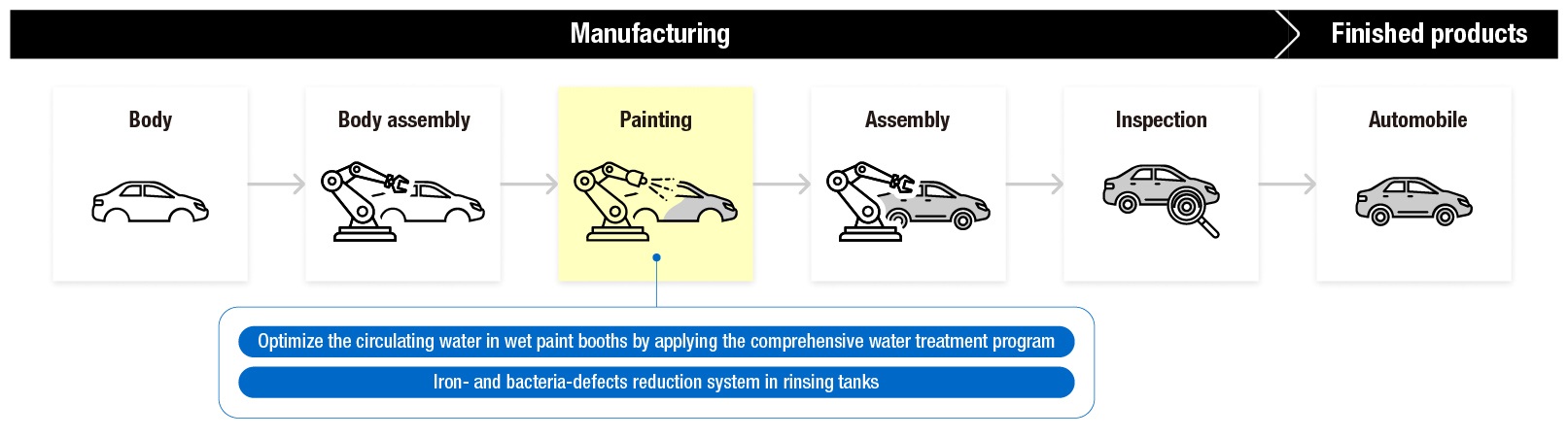

Automotive manufacturing process

Challenges and solutions for the automotive industry

01. Optimize the circulating water in wet paint booths by applying the comprehensive water treatment program, which contributes to stable operation, work environment improvement, waste reduction, and workload reduction

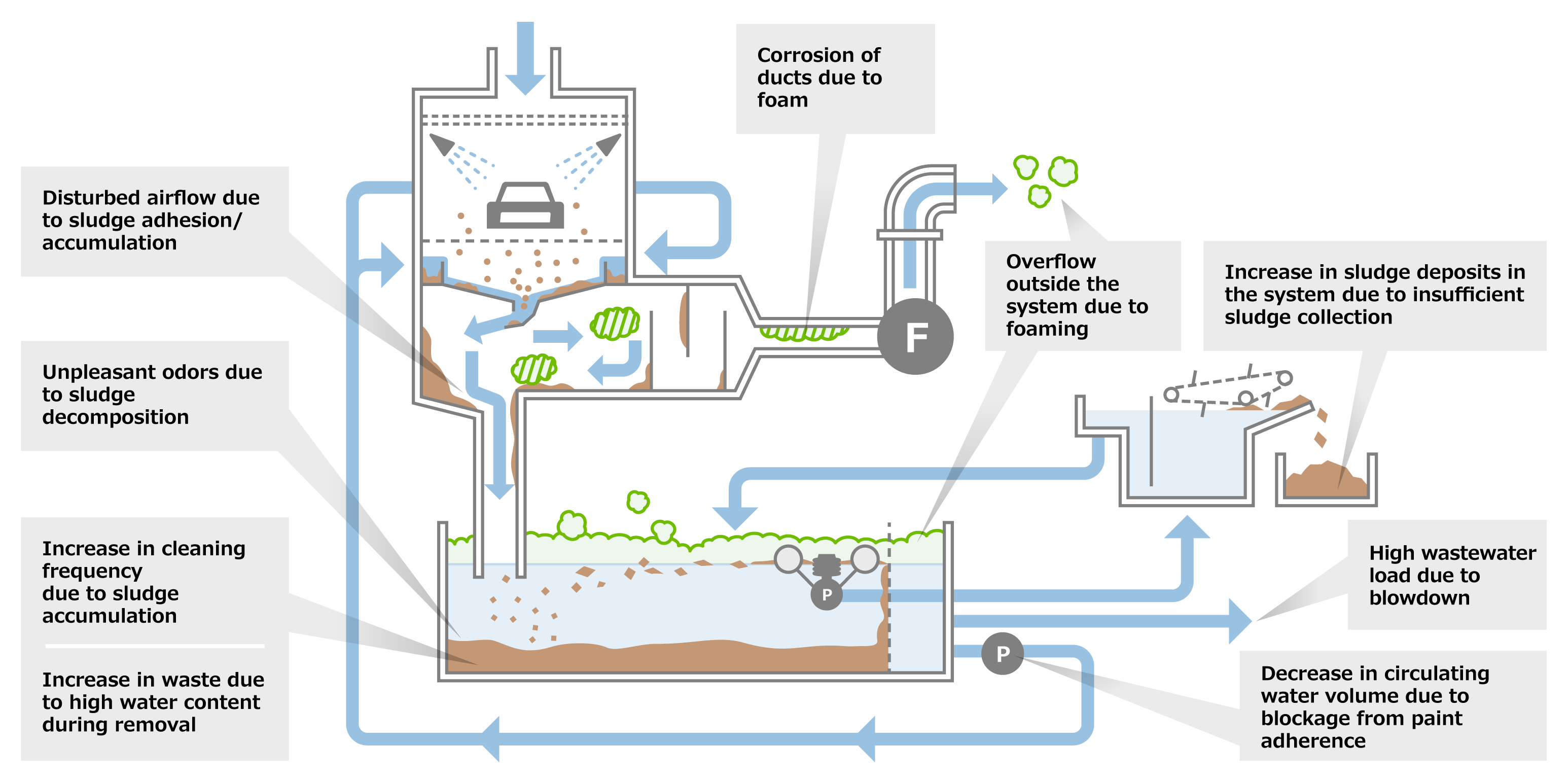

Challenges

To prevent painting defects, automobile paint booths are equipped with a device at the bottom of the booth that suctions excess paint from the air and collects it in circulating water. Chemicals are injected to separate the paint from the water, and the water is recirculatedwhile the paint is disposed of as sludge. Because solvent paint is highly adhesive, if the injected chemicals are not effective enough, paint may adhere to the pipes, pumps, and other areas, clogging them. Not only does this lead to a reduction in the amount of circulating water and the inability to collect excess paint from the air, it leads to serious problems like painting defects or stopping the painting process. In addition, when the paint separates from the water and air is drawn in, it causes foaming. This places a high burden on wastewater treatment. When it accumulates in the tank, it results in unpleasant odors and increases the frequency of maintenance.

Solutions

The comprehensive circulating water treatment program consists of four products and services. The combination of the Kuristuck ™ series, which perform paint detackification and coagulation treatment, and S.sensing™ KS, which monitors water quality and automatically controls the amount of chemicals injected, maintains water quality to prevent blockages and foaming in pipes, pumps, and other equipment. Separated paint is processed by the Kuristacker™, a stable automatic collection system. Accumu lated paint is resurfaced and processed by the Deposited Sludge Resurfacing System™. Beause ofthe program, sludge can be removed at a lower moisture content than when discharged by vacuum or other means. This program can solve the various problems shown in the figure below and contribute to reducing waste and maintenance, keeping cleanliness condition, and stable operations.

Waste reduction

Labor resource saving

Keeping cleanliness condition

Stable operation quality

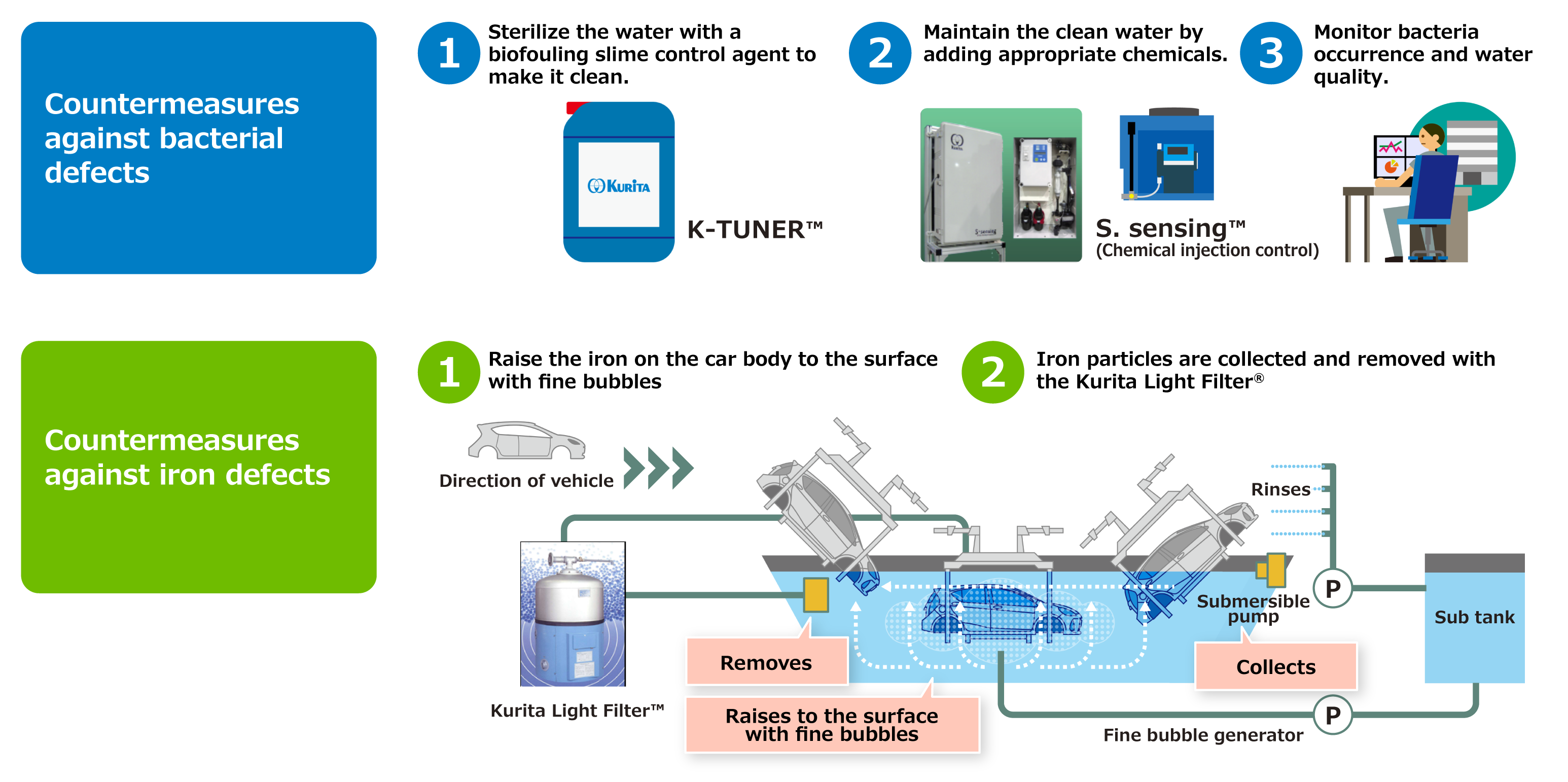

02. Applying the iron- and bacteria-defects reduction system prevents water quality deterioration in rinsing tanks during surface treatment and electrodeposition processes, improving productivity

Challenges

Painting a car when there is iron powder generated from metal processing or bacteria generated can cause rework such. In addition, the deterioration of water quality increases the frequency of filter replacement and equipment cleaning, resulting in reduced productivity.

Solutions

A microbubble generator and upward-flow rapid filtration Kurita Light Filter™ are installed in the rinsing tank to raise metal powder and other foreign substance from the bottom of the tank remove them. In addition, the biofouling control agent K-TUNER™ is injected into the tank to prevent the formation of bacterial matter and blockage of the filter. Furthermore, the Kurita Group's proprietary S.sensing™ CWS, which continuously monitors the concentration of chemicals and automatically controls the amount, is used to control water quality at the optimal concentration of chemicals and maintain a clean environment in the rinse tank. These solutions prevent the deterioration of water quality, reduce maintenance, and improved productivit y.