Power | Industries

Bolstering electricity, which supports daily life, by wate

To introduce the solutions for the power industry.

Kurita Group solutions for the power industry

Electricity is essential for the maintenance and development of society and industry. Power generation methods have been diversifying in recent years due to increasing demand and environmental impact. In addition to thermal and nuclear power, power generation from renewable energy sources, such as solar, wind, hydro, geothermal, and biofuels, is increasing. The Kurita Group provides equipment cleaning services to thermal power plants that use coal and liquefied natural gas (LNG) as fuel for power generation and at nuclear power plants for water purification equipment, pure water producing equipment, chemicals and equipment regarding condensate, and wastewater treatment, and boilers. These solutions contribute to stable operation and reduction of environmental impact. In addition, for renewable energy power plants, methane fermentation facilities can effectively use methane gas produced by methane fermentation of industrial and general waste as fuel for power generation and boilers. As well as these facilities can use boilers and cooling water treatment chemicals to maintain and improve heat transfer coefficient for geothermal power plants are provided, contributing to the realization of a decarbonized society through reductions in GHG emissions.

Challenges and solutions for the electric power industry

01. Thermal power generation:Remove scale reliably from OT-applied boilers to stablize operation

Challenges

In thermal power plants, steam generated in the boiler is sent to the turbine to generate electricity, and the steam used for power generation is returned to water in the condenser and then fed back to the boiler. Water treatment in boilers and condensers is essential because impurities in the boiler feedwater can cause scale to adhere to boilers and turbines. Oxygenated treatment (OT) is also performed on boilers at thermal power plants to reduce the frequency of cleaning, thus making it more difficult for scale to adhere. Therefore, while OT-applied boilers have the advantage of not having to be cleaned for a long period of time, adhered scale is difficult to dissolve with chemicals and difficult to remove.

Solutions

The chemical cleaning service for OT-applied boilers at thermal power plants first analyzes the composition of scale and conducts dissolution tests and then selects chemicals that are highly effective in cleaning persistent and insoluble scale. Then, sludge removal equipment, such as sludge catchers and filters, are installed in the boiler cleaning system to clean the scale using selected chemicals and prevent the sludge generated from returning to the boiler, ensuring to remove sludge. In addition to contributing to the stable supply of electricity by realizing stable boiler operation, the system also contributes to water conservation by reducing the amount of cleaning water used compared to conventional chemical cleaning.

Water savings

Stable operation quality

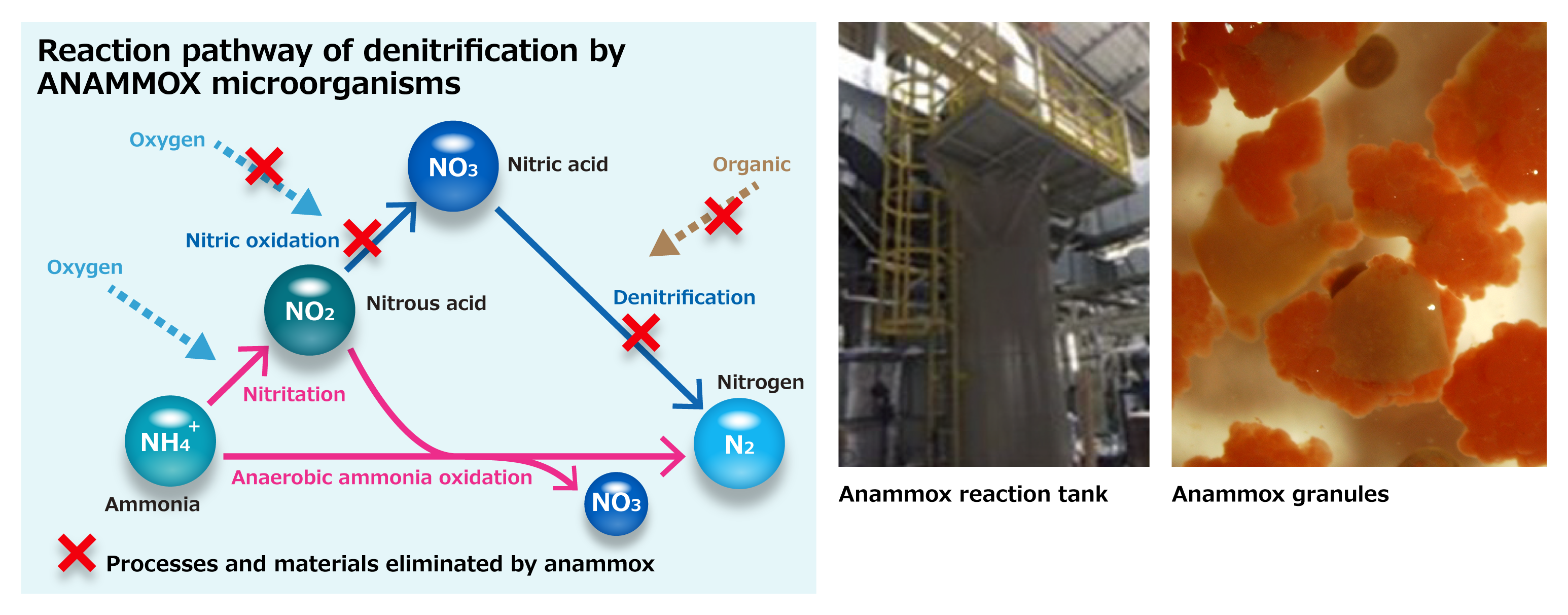

02. Biogas power generationApply the ANAMMOX Process™, a highly efficient treatment of digestion liquid, reducing energy consumption and sludge generation

Challenges

Biogas is a methane-based gas produced by the fermentation of organic matter in industrial and general waste through the power of microorganisms. In wet methane fermentation, one of the methods of biogas generation, where raw materials with high water content, is when digestion liquid containing high concentrations of nitrogen compounds is generated when methane gas is produced. The nitrification-denitrification method commonly used to treat wastewater from this digestion liquid is a two-step process. The nitrification process carries out oxidation from ammonia to nitrous acid and then to nitric acid. The second step is denitrification process to reduce nitric acid to nitrogen gas. The nitrification process requires a lot of aeration power to activate bacterial activity, and the denitrification process requires a denitrification carbon source (such as methanol), so the growth of bacteria also creates excess sludge.

Solutions

In wastewater treatment of digestion liquid, the introduction of a process utilizing ANAMMOX bacteria can s ignificantly reduce the amount of energy used for aeration, the amount of methanol and other substances injected, and the amount of sludge generated compared to the general nitrification-denitrification method. In addition, the overall installation space of the equipment can be significantly reduced due to the smaller capacity of the water tank required for the treatment. This process can be applied to a wide range of fields, including digestion liquid discharged from methane fermentation, semiconductors, urban sewage, and livestock production.

Energy savings

GHG emissions reduction

Reduction of Resource Input

03. Geothermal power generationApply solutions to prevent corrosion and scale, stablizing operations and increasing productivity

Challenges

At geothermal power plants, steam generated deep underground is extracted to rotate turbines and generate electricity. Hot water is extracted along with the steam, and the conditions of the hot water, such as water temperature and pH, can cause corrosion and scale damage to the underground piping and aboveground equipment. This damage can result in deterioration of stable operation and power generation efficiency, so power generation facilities must be periodically shut down for cleaning and maintenance.

Solutions

The Kurita Group identifies the substances that cause this damage and selects and applies appropriate water treatment chemicals to prevent corrosion and scale. This contributes to stable operations and improves the efficiency of power generation by reducing the downtime of power generation facilities. This contributes to higher productivity.