Food and Beverage| Industries

Water treatment as the essential foundation of safety

To introduce the solutions for the food and beverage industry.

The Kurita Group solutions for the food and beverage industry

In the food and beverage manufacturing process, where safety and sanitation are strictly controlled, filtered water and pure water are used for various purposes, such as washing, heating, and cooling product ingredients and containers. In addition, wastewater from the manufacturing process contains a large amount of organic matter derived from byproducts generated during manufacturing, which must be treated. Factories that manufacture a wide variety of food and beverage products require stable wastewater treatment that can adapt to fluctuations in wastewater quality caused by changes in production items. The Kurita Group combines filters, reverse osmosis (RO) membranes, ion exchange resins, and other technologies to provide water treatment equipment that produces safer water for your specific needs. In wastewater treatment, biological treatment systems that utilize the power of microorganisms for highly efficient treatment of organic wastewater unique to the food and beverage industry, as well as other optimal wastewater treatment systems that provide stable treatment based on factors such as the wastewater quality, properties, water volume, and discharge standards set by law, are provided.

Challenges and solutions for the food and beverage industry

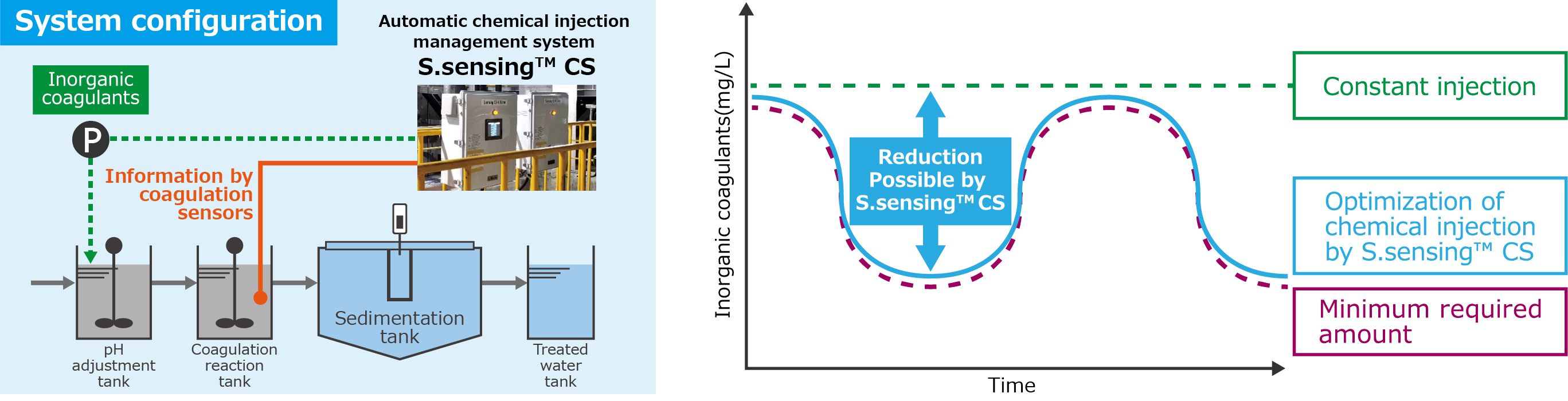

01. To optimize the dosage of wastewater treatment chemicals by using S.sensing™ CS and organic coagulant, achieving stable operation and cost reduction

Challenges

Wastewater from food factories often contains emulsifiers (surfactants). As a general wastewater treatment flow, emulsifiers, etc., are coagulated by injecting inorganic coagulants such as polyaluminum chloride (PAC), a wastewater treatment chemical, and then separated by pressurized flotation followed by biological treatment. Since product items and production volumes change daily, the concentration of emulsifiers in wastewater also fluctuates. In order to ensure stable wastewater treatment, the amount of inorganic coagulant injected is generally set according to the high concentration of emulsifier. Therefore, low concentrations of emulsifiers result in over-injection, which increases chemical costs, chemical-derived sludge generation, and sludge disposal costs.

Solutions

The Kurita Group's proprietary S.sensing CS automatic chemical injection volume control system, which uses a coagulation sensor, optimizes the chemical injection volume by automatically controlling the injection volume of inorganic coagulants with high precision according to changes in the concentration of emulsifiers. This system enables both stable operation by stabilizing wastewater treatment without any labor and reducing the chemical cost and the chemical-derived sludge amount generated (resource input). In addition, by using Zeta Ace™ P-702, an organic coagulant that provides a coagulation effect with only a small amount of injection, the amount of inorganic coagulant injected can be significantly reduced, further reducing the amount of chemical-derived resource input.

Reduction of Resource Input

Cost reduction

Labor resource saving

Stable operation quality

02. Applying a decolorizer and S.sensing™ CS, which incorporates a colorimeter, ensuring stabilization of the quality of treated water and cost reduction

Challenges

Wastewater from beverage factories contains colored components, such as tea and coffee. Although the color components need to be removed in wastewater treatment, they are not easily removed by biological treatment for general organic matter (CODMn), so inorganic coagulants such as ferric chloride solution, a wastewater treatment chemical, are injected in large amounts and the color components are separated by coagulation sedimentation treatment. The concentration of color components in wastewater varies depending on various conditions, such as product type. To ensure stable wastewater treatment, the amount of inorganic coagulant injected is generally set according to the high concentration of color components. As a result, chemical costs, chemical-derived sludge generation, and sludge disposal costs are increasing.

Solutions

The S.sensing CS, which incorporates a colorimeter, continuously measures inter-floc turbidity and treated water color, and automatically controls the amount of chemicals injected from the perspective of both coagulation effect and color components, thereby achieving both stable operation by stabilizing wastewater treatment without labor and reducing the amount of sludge (resource input) generated from inorganic coagulants. In addition, when used in combination with the decolorizing agent Zeta Ace™ D-801, the amount of inorganic coagulant injected is significantly reduced, further reducing the input of chemical-derived resources.