Oil Refining and Petrochemical | Industries

Supporting the stable operation of equipment with water technology

Introduce the solutions for the oil refining and petrochemical industries.

The Kurita Group's solutions for the oil refining and petrochemical industries

To ensure stable operations at oil refineries and petrochemical plants, it is essential to prevent damage, such as contamination and corrosion, on the various equipment used in the production and manufacturing processes. The Kurita Group provides a wide range of services to meet the various needs, such as corrosion inhibitors, anti-contamination agents, scale inhibitors and dispersants, fuel additives, cleaning agents, and cleaning equipment.

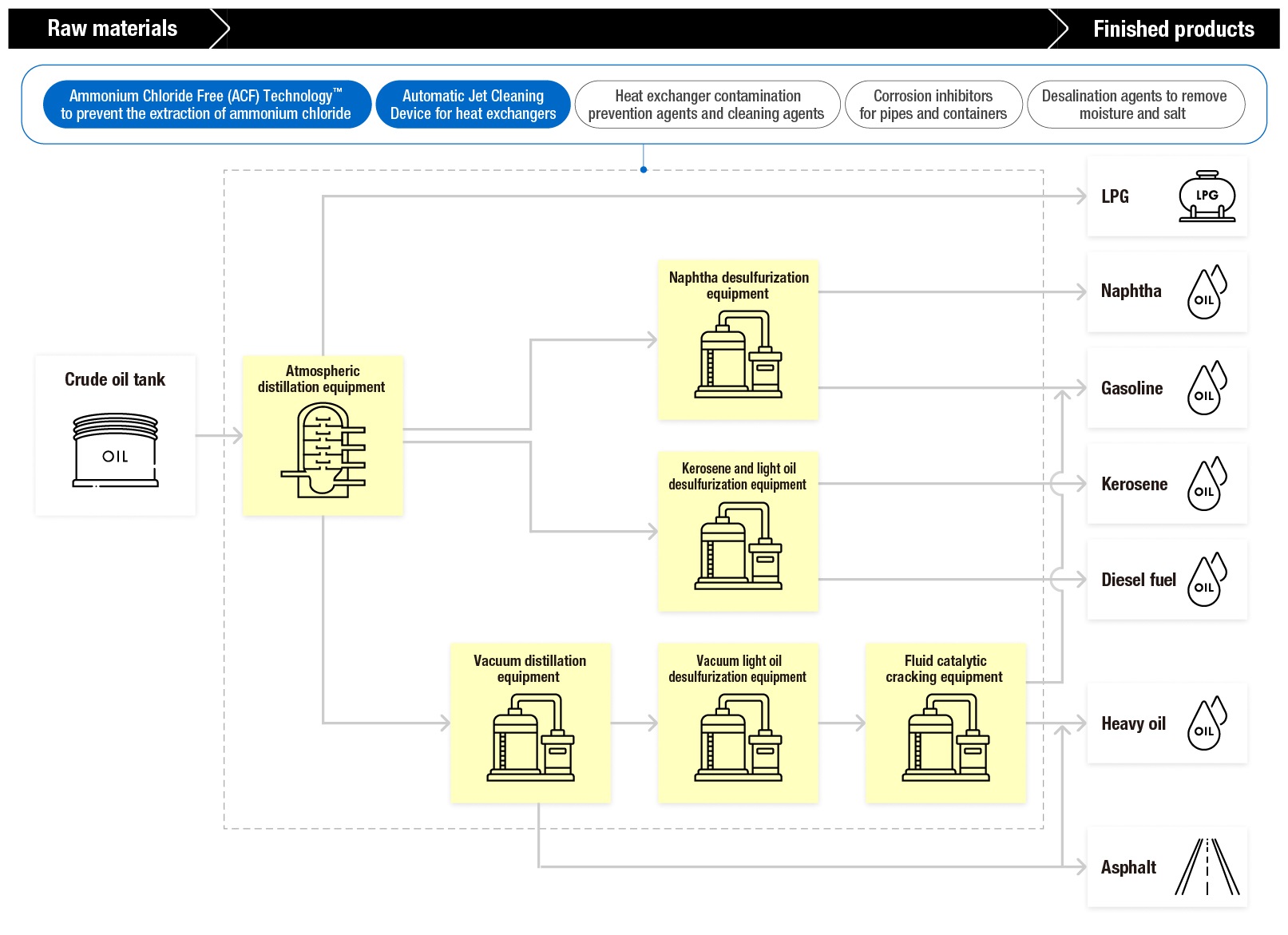

Oil refining process

Challenges and solutions in the oil refining and petrochemical industries

01. Apply Ammonium Chloride Free (ACF) Technology™ to prevent the extraction of ammonium chloride, which can lead to blockages and corrosion risks in distillation columns, stablizing operations and improving productivity

Challenges

In oil refining plants, crude oil is heated in a distillation column and turned into steam, and then gasoline, diesel fuel, etc., are refined by taking advantage of the differences in their respective boiling points. In oil refining, in response to factors like tightening of regulations, there are efforts to increase the production of diesel fuel with low sulfur content. When operating a distillation column at a temperature to match the low boiling point of diesel oil and if the steam pressure of the gas generated from the impurities in the crude oil is exceeded, there is an increased risk of extraction of ammonium chloride an impurity contained in the residual oil fraction in the distillation column. If this scale adheres and accumulates inside distillation columns and heat exchangers, blockages and corrosion can occur, leading to a rise in the risk of reduced plant productivity and emergency shutdowns.

Solutions

It applies chemicals that replace ammonium chloride with Ammonium Chloride Free (ACF)-Cl to equipment, such as distillation columns. Ammonium Chloride Free (ACF)-Cl has high fluidity, so it is difficult to accumulate inside equipment and its low corrosiveness to characterize it. Reducing the risk of ammonium chloride extraction when the temperature drops inside the distillation column stablizes operation of petroleum refining plants and increases production of diesel fuel.

Stable operation quality

Productivity improvement

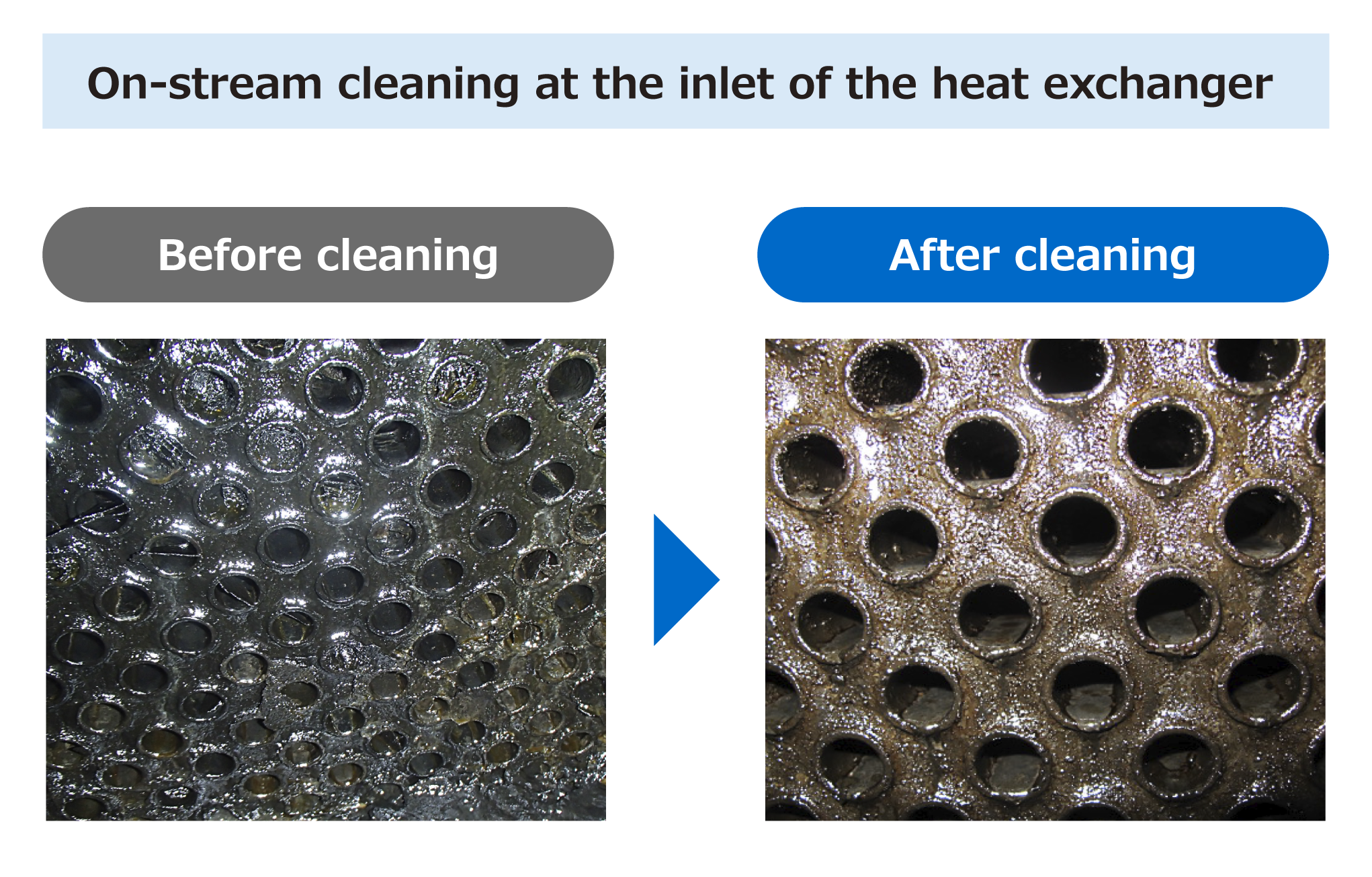

02. Safely and reliably remove dirt from the heat exchanger by the automatic jet cleaning device to stablize operation.

Challenges

Oil stains on heat exchangers in oil refinery plants can cause energy loss due to reduced heat transfer coefficient. To remove these stains, jet cleaning with high-pressure water is typically used. However, this method requires time and effort to remove deposits. In addition, since the nozzle is operated directly by hand, there can be concerns regarding work safety.

Solutions

The automatic jet cleaning device, which sprays a large volume of high-pressure jet water into the heat exchanger, can reliably remove dirt, thereby contributing to stable operation. In addition, the high-pressure water nozzles and hoses are not handled directly by the operator, so the cleaning can be done safety.