Electronics| Industries

Supporting the electronics industry with water refined through technology

Introduction of solutions for the electronics industry.

Kurita Group solutions for the electronics industry

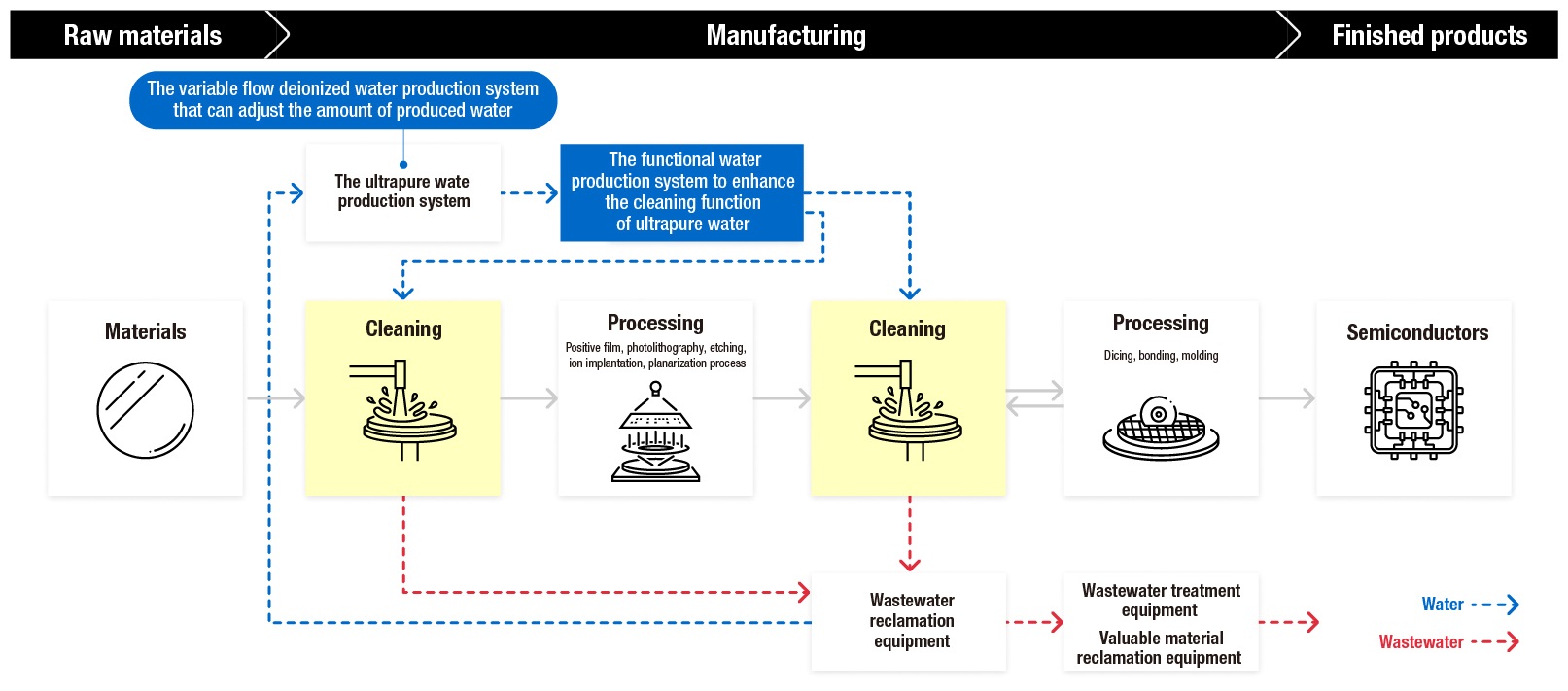

In the manufacturing of silicon wafers, semiconductors, and various electronic components in precision equipment, ch emical substances and foreign matter can cause product yields to suffer. Thereby, a cleaning process is essential to remove chemical substances and foreign matter, involving ultrapure water, which is as close to pure H₂O as possible, or functional water in which chemicals or gases are dissolved. The Kurita Group provides an ultrapure water production system and functional water production system that combine pretreatment equipment(such as filters), deionized water production system (such as reverse osmosis (RO) membranes and ion exchange resin towers), and subsystems (such as UV sterilization equipment and UF membranes). In addition, Kurita Group offers treatment equipment to treat organic and inorganic wastewater, wastewater reclamation equipment to recover and raise water, and valuable material reclamation equipment to recover and reuse phosphoric acid, hydrofluoric acid, and other substances in wastewater.

Semiconductor manufacturing process

Challenges and solutions for the electronics industry

01. Applying the variable flow deionized water production system, which can produce the required amount of ultrapure water when needed, reduces use of electric power derived from RO membrane water pumps

Challenges

The ultrapure water production system consists mainly of pretreatment equipment, a deionized water production system, and subsystems. Of these, the deionized water production system consumes the largest amount of electricity; most of which is used to power the equipment pumping water to the RO membranes. In conventional ultrapure water production, ultrapure water is generated at the designed flow rate regardless of the amount used to maintain water quality. Then u nused ultrapure water is circulated to the deionized water production system in the previous stage. When the amount of water used is low, circulation is increased, resulting in increased power consumption by the RO membrane.

Solutions

The Kurita Group has developed a variable flow deionized water production system that automatically adjusts the volume of treated water according to the volume used and maintains quality even when the volume fluctuates. This is done through overall optimization, including improvements to the way water is fed into the desalination and concentration chambers of the continuous electrode-ionizer (CEDI). This enables the production of the necessary amount of ultrapure water, contributing to the reduction in power consumption and GHG emissions.

Energy savings

GHG emissions reduction

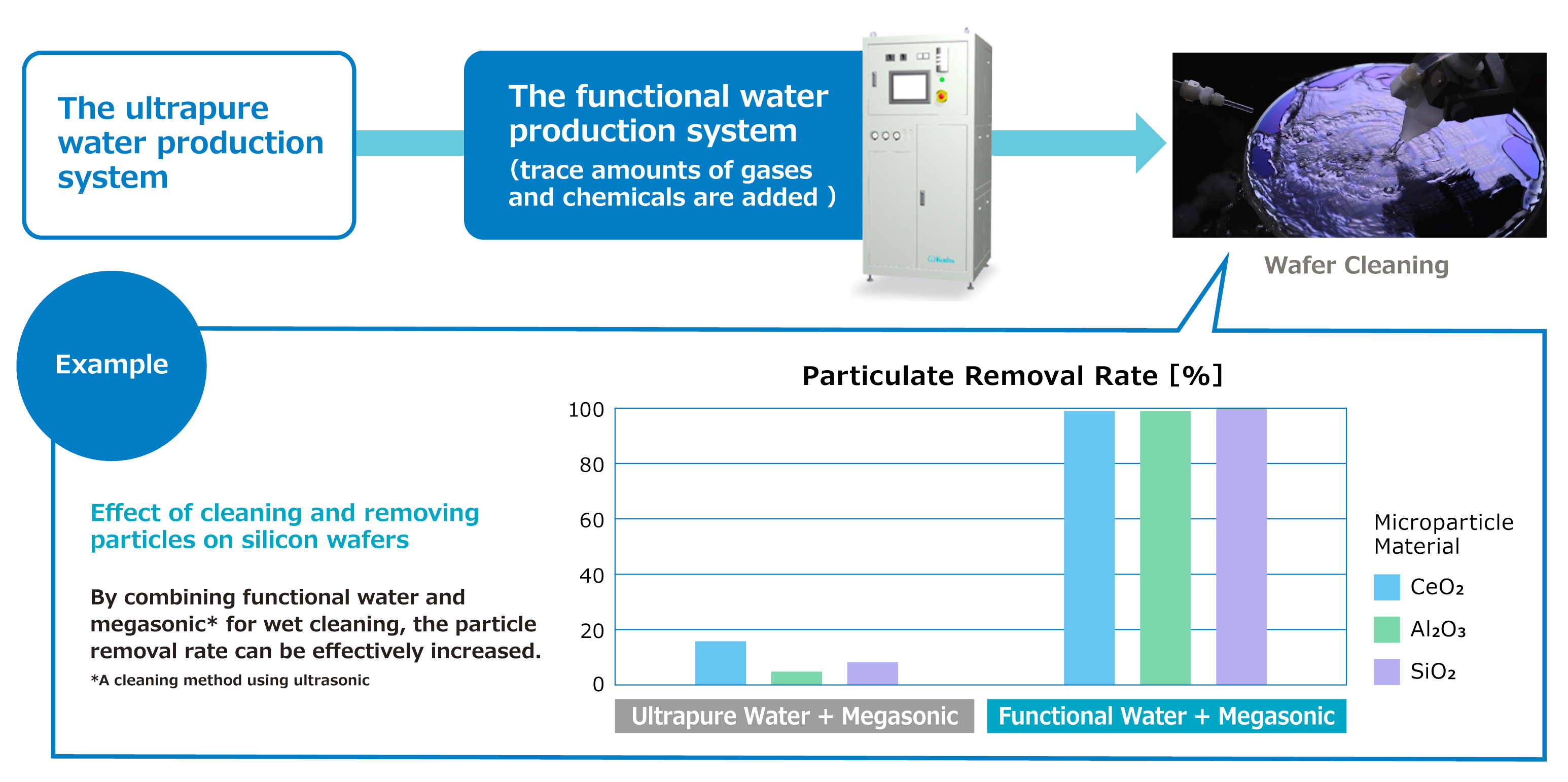

02. Applying the functional water production system, which improves the impurity removal performance and material dissolution inhibiting effect of ultra-pure water, reduces use of cleaning chemicals, conserves water, and improves yield

Challenges

A large amount of cleaning chemicals are used in the cleaning process of semiconductors, liquid crystal panels, and electronic components. Because of the recent miniaturization of semiconductors, more chemicals are needed to improve cleanliness. Therefore, reducing the amount of cleaning chemicals used has become a challenge. In addition, new metallic materials are often used in the latest semiconductors. In the process that uses chemicals to clean and rinses with ultrapure water, the ultrapure water can cause dissolution of materials and degradation of the surface smoothness. These can lead to loss of product.

Solutions

The Kurita Group provides the functional water production systems as an ancillary unit for semiconductor manufacturing equipment. Functional water is ultrapure water in which trace amounts of gases and chemicals are added to control pH and oxidation-reduction potential, improving impurity removal performance. This improvement enables cost and resource input reduction through the decreased use of cleaning chemicals and increased water conservation. It also prevents dissolution of new metallic materials and deterioration of surface smoothness of semiconductors, leading to improved yield.