Iron and Steel | Industries

Harness the power of water to aid in iron making

To introduce the solutions for the iron and steel industry.

The Kurita Group solutions for the iron and steel industry

In the iron and steel manufacturing process, water is used in various ways. Cooling water systems are used to cool equipment, and products with high thermal loads, such as furnaces, and dust collection water used to clean exhaust gas generated by furnaces, several problems can occur. This can include insufficient equipment cooling due to scale adhesion and blockage of flow channels. Problems can also be caused by raw materials such as iron ore and coal which are used for iron and steel production. These include the adhesion and blockage of raw materials in transport, and in storage facilities when exposed to moisture as well as the generation of dust when moisture decreases due to excessive drying. The Kurita Group provides water treatment technologies and solutions that maintain cooling efficiency in manufacturing processes and enable the recycling of dust collection water, reforming raw materials in raw material yards, and dust prevention and control contributing to stable operation, improved productivity, and reduced environmental impact in iron and steel mills.

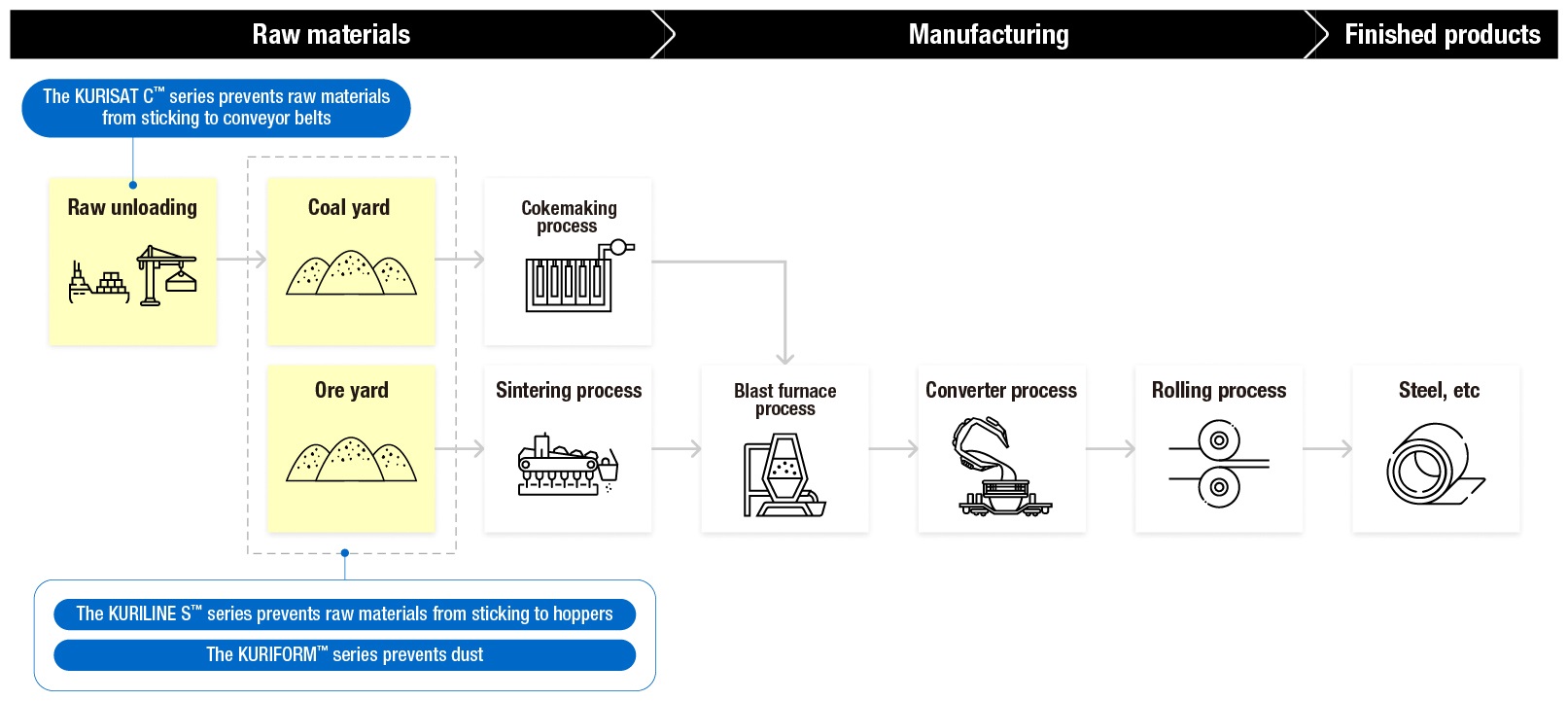

Iron and steel production process

Challenges and solutions in the iron and steel industry

01. To apply the raw material reforming agent KURISAT C™ series that prevents the adhesion of raw materials for iron and steel, ensuring reduced costs and improved productivity by eliminating unloading delays

Challenges

Iron ore and coal, which are used as raw materials for iron and steel production, can increase their adhesion and flowability when the moisture content of the raw materials rises due to an increase in fine materials or rainfall. When unloading from a raw materials carrier in these conditions, blockages and ore fall can occur due to the adhesion of the raw materials on the conveyor belt and transfer chute. Interrupting unloading to clean the transport equipment can lead to an increase in demurrage for the raw material transport ship, and a decrease in productivity due to the delay in the supply of raw materials.

Solutions

The raw material modifier KURISAT C series enables the moisture in the raw material to be trapped in granules which improves adhesion and fluidity to prevent blockages and backflow in the conveying equipment, thereby reducing demurrage and improving productivity by eliminating unloading delays. In addition, by combining sensing technology that can automatically control the amount of chemicals injected by measuring the moisture content of the raw material, using a moisture sensor, the amount of chemicals injected is optimized in response to fluctuations of the raw material being transported on the conveyor belt.

Cost reduction

Productivity improvement

02. To apply the raw material modifier KURILINE S™ series for preventing the adhesion of recycled raw materials to prevent blockages in the hopper, thereby contributing to improved productivity, reduced resource input, and cost reductions

Challenges

The raw materials for iron and steel stored in the outdoor yard become more adhesive when moisture rises, due to rain or spraying. If there is a blockage or gushing out in the storage tank during transport on the belt conveyor, the supply of raw materials will stop, which will lead to a decrease in productivity in subsequent processes. In particular, fine dust and slag, which are recycled materials, can easily cause blockages in the hopper and make it difficult to use when the moisture content rises. If the amount of recycled material used decreases, the amount of new material increases, leading to higher costs.

Solutions

The raw material modifier KURILINE S series mitigates adhesion issues of raw materials for iron and steel, production .It prevents blockage and overflowing during the conveying process by absorbing moisture and reducing adhesiveness. This improves productivity and stabilizes the amount of recycled raw materials used, which contributes to reducing resource input and lowering costs.

Reduction of Resource Input

Cost reduction

Productivity improvement

03. To apply the dust control KURIFOAM™ series for improving the working environment in the raw material yard and preventing air pollution

Challenges

If the raw material is fine and has low moisture content, it can scatter from the pile (pile of raw materials), belt conveyor, or transfer chute, due to wind, or other factors, generating dust This dust can deteriorate of the work environment and cause air pollution, necessitating prevention measures.

Solutions

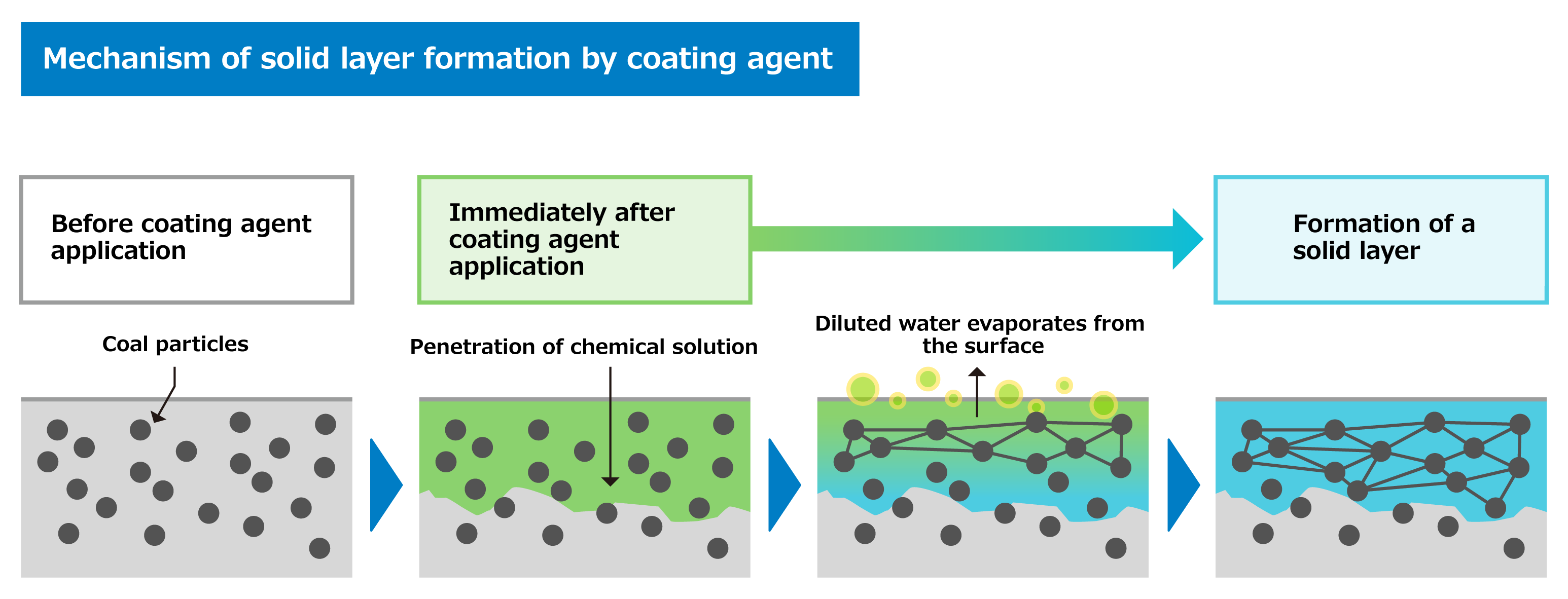

The Kurita Group offers an array of dust control technologies to suit different applications, and environments including coating agents that provide both dustproofing and waterproofing effects, and dust-proofing agents that have water retention and foaming properties, thereby contributing to the reduction of environmental impact and the improvement of working environments. The KURIFOAM series of dust prevention agents include film-forming agents for piles and water -retaining agents for dust control . For example, the piles in the raw material yard are coated with a unique coating agent that has both dustproof and waterproofing effects and can simultaneously control scattering, and the rise of moisture due to rainfall. In the transport process, a spraying device applies a foam to the belt conveyor by a spraying device. A foam-type dust control agent is applied to prevent dust generated from the transfer chute, and a road dust control that prevents dust by retaining water is applied to unpaved roads.