Pulp and Paper | Industries

Clean water can maintain paper quality

Introduce the solutions for the pulp and paper industry.

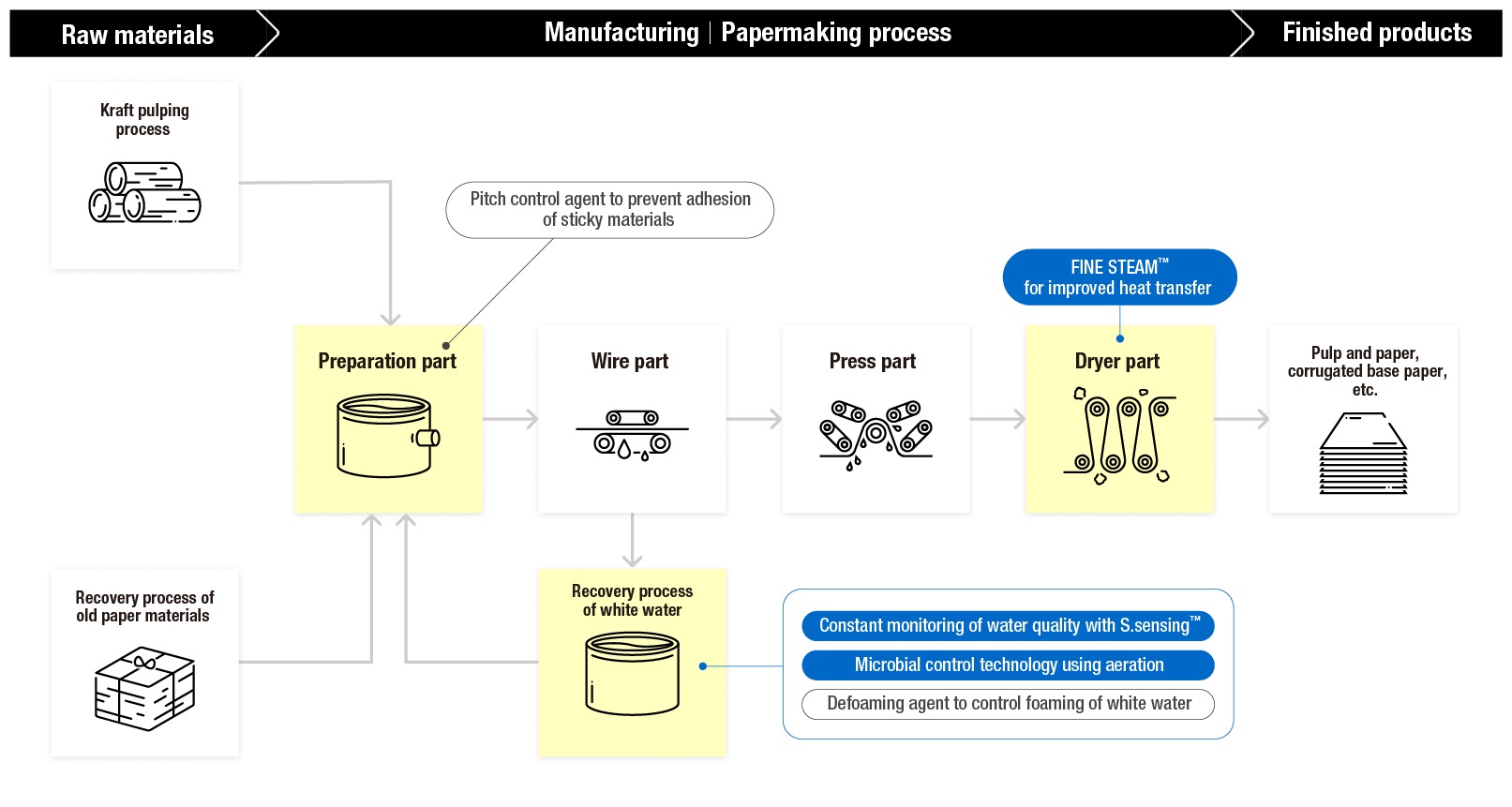

The Kurita Group’s solutions for the pulp and paper industry

Large amounts of water is used and recycled process to produce the raw material pulp for paper and in the papermaking process. Therefore, water quality-related problems occur: scale or sediment derived from hardness components in the water, foaming, paper loss and holes caused by pitch (adhesive substances contained in wood and wastepaper), as well as reduced product quality derived from microorganisms such as bacteria and mold in the water that has dissolved the pulp. In addition, the adhesion of water film to the heat exchanger used to dry wet paper causes a reduction in heat transfer, resulting in energy loss. The Kurita Group provides a variety of solutions that contribute to improved productivity, such as preventing water quality degradation caused by scale, foam, pitch, and biofouling (a sticky, muddy material in which bacteria, mold, algae, and other microbes mix with sediment and dust) in the overall pulp and paper manufacturing process and improve the heat transfer rate in heat exchangers.

The pulp and paper manufacturing process

Challenges and solutions for the pulp and paper industry

01. S. sensing™ continuously monitors water quality fluctuations in the pulp and paper manufacturing process for stable production quality, thereby improving productivity

Challenges

If water used in the various processes of paper and pulp production becomes contaminated, the production yield deteriorates due to paper breakage and holes. In addition, microorganisms in the water can cause problems, such as reduced product quality, which in turn leads to lower productivity. Factors that can cause water quality deterioration include the concentration of recycled water and rotting of raw materials for products such as wood chips that accumulate in the circulation line. To prevent productivity loss due to water quality fluctuations, it is necessary to identify the causes through continuous monitoring of water quality data and to take countermeasures accordingly.

Solutions

The S.sensing unit installed in a customer’s main production process monitors water quality data at all times. The correlation between the obtained monitoring data and product quality is analyzed based on the customer's operation data to identify the water quality affecting the operation and to understand the fluctuation trend. Kurita then provides a one-stop solution from root cause investigation to resolution, thereby contributing to improved productivity by stabilizing product quality.

Productivity improvement

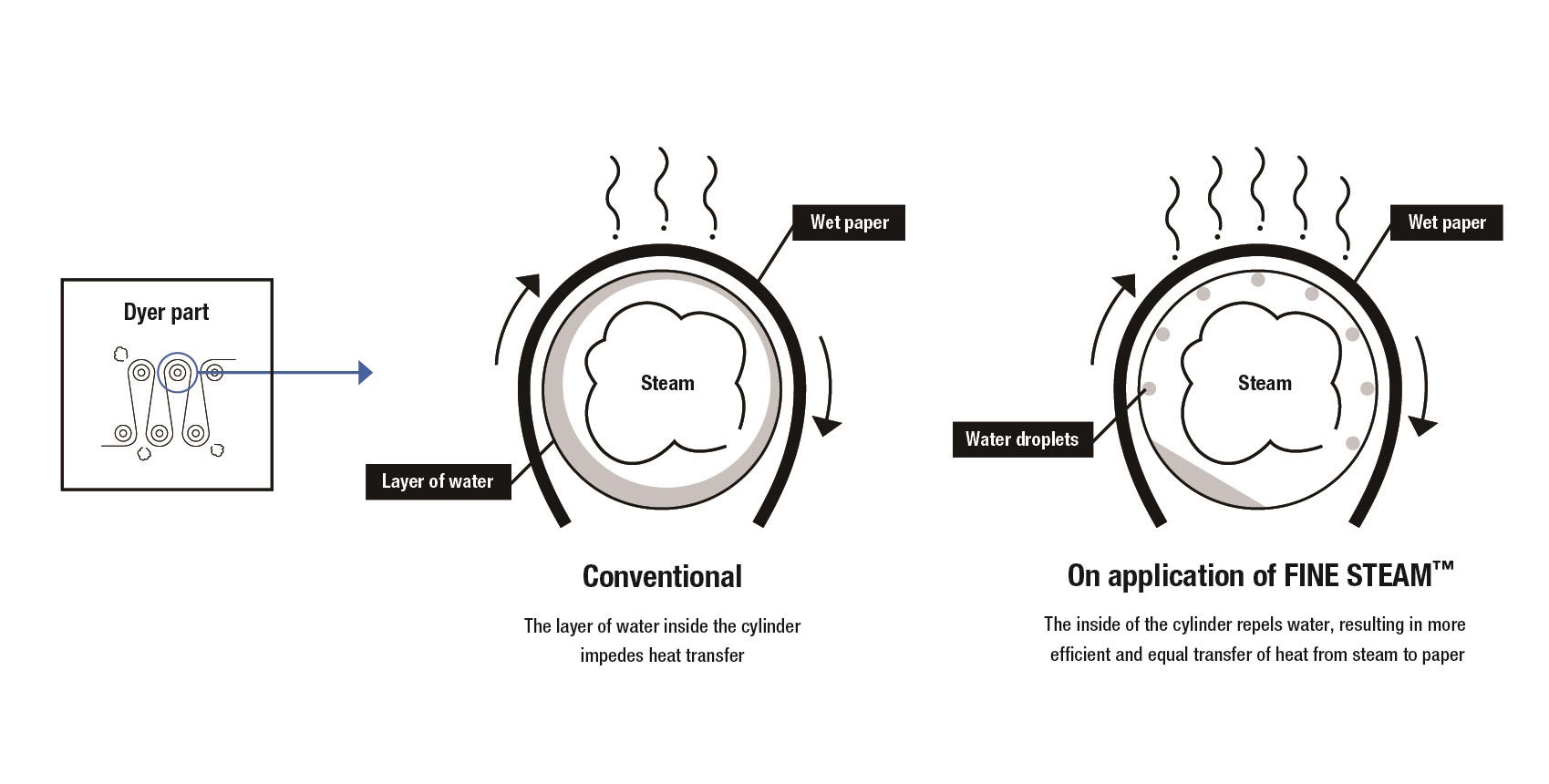

02. FINE STEAM™, which utilizes our proprietary Kurita Dropwise Technology™, improves productivity, saves energy, and reduces GHG emissions by improving the heat exchanger's transfer coefficient.

Challenges

In the dryer part of the papermaking process, a lot of steam is used to dry wet paper. If water films are formed on the inner surface of the cylinder roll due to steam condensation, the heat transfer coefficient will decrease, leading not only to lower productivity but also to increased steam and energy consumption.

Solutions

FINE STEAMTM is added to the steam line to form a water-repellent film on the inner surface of the cylinder rolls in the dryer part, preventing the formation of a water film and contributing to improved productivity and energy savings and reduced GHG emissions. In combination with the continuous residual concentration measurement solution S.sensing™ DW a packaged solution that includes automatic control of chemical injection in line with fluctuations in steam volume and analysis of customers' operation, operational data, and steam reduction effects.

Energy savings

GHG emissions reduction

Productivity improvement

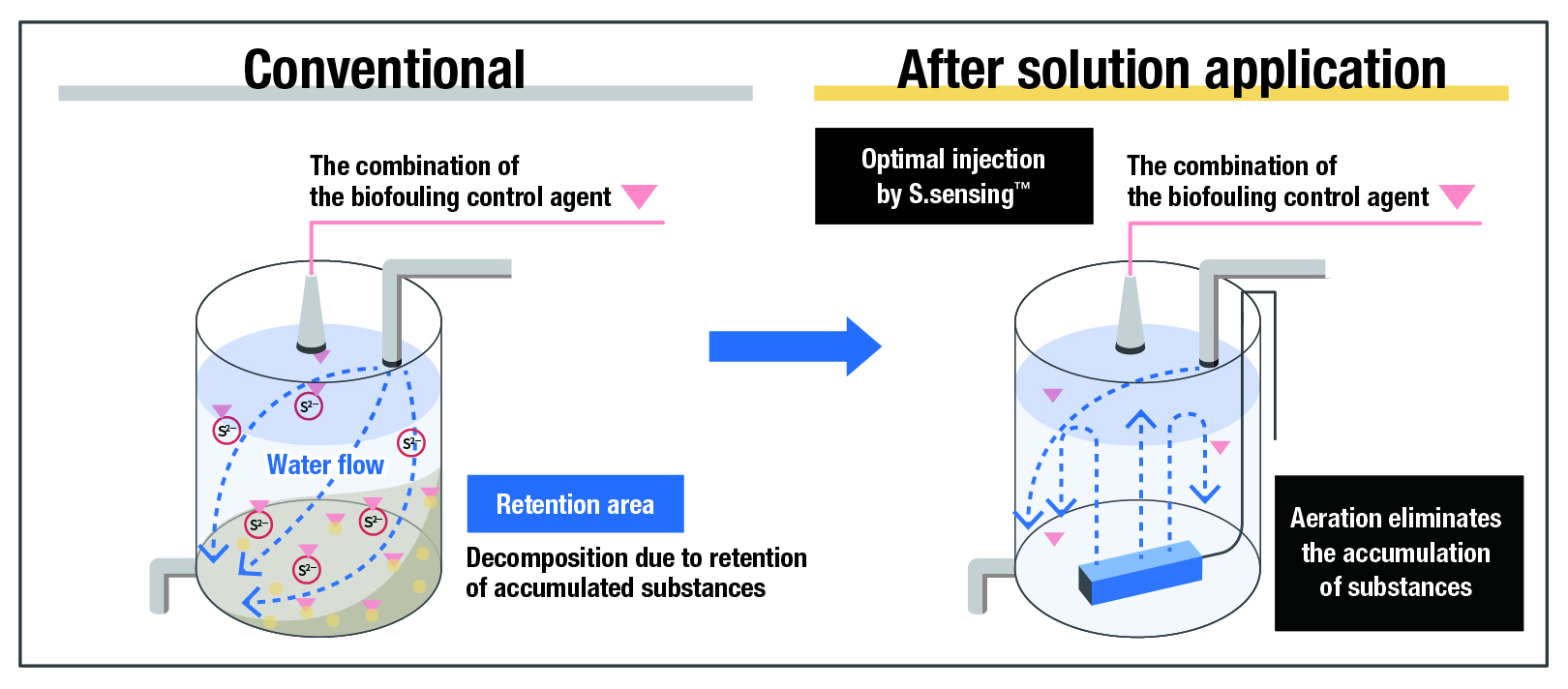

03. Combining Microorganism control technology combined with aeration improves productivity by stabilizing product quality and improved sanitation

Challenges

Microorganisms are generated in the pulp raw material process and in the paper making process during water circulation. Since the generation of microorganisms affects product quality, the use of biofouling control agent is common. However, the treatment effect of the biofouling control agent may decrease due to the decomposition of material accumulated in the bottom of the storage tank, reducing product quality and creating odor.

Solutions

The combination of the biofouling control agent and Kurita Group's proprietary aeration technology enhances the effect of the chemical while preventing the retention of raw materials, contributing to improved productivity and sanitation by stabilizing product quality. In addition, when combined with S.sensing™, the amount of chemical injected can be automatically adjusted to water quality fluctuations and optimize the amount of chemical used.